Utilizing robotic cables can pose a multifaceted challenge due to numerous factors that must be taken into account to ensure optimal effectiveness and dependability.

From the careful selection of appropriate cable types to the effective management of cable routing and stress, comprehending the intricacies surrounding robot cables is essential for achieving successful robotic operations.

Now, let's explore some significant intricacies associated with the utilization of robot cables.

1. Choose a suitable cable:

When it comes to robot applications, selecting the right cable is of utmost importance. It is crucial to assess various factors, including flexibility, durability, and resistance to environmental conditions like temperature, chemicals, and abrasion.

Robot cables are specifically designed to withstand repetitive motion and bending, ensuring that signal integrity and power transmission remain uncompromised.

2. Ensure signal integrity:

In robot applications, preserving signal integrity is of utmost importance, especially in scenarios involving data transmission or precise control signals.

To minimize signal loss, noise, and distortion, various factors must be taken into account, including cable length, shielding, and interference.

Employing appropriate cable shielding and grounding techniques can effectively reduce signal interference, facilitating accurate communication between different robot components.

3. Flexibility and twisting radii:

When it comes to robots, it is common for cables to undergo frequent bending and twisting motions.

Therefore, cables with excellent flexibility and a small bending radius are favored to prevent excessive strain and premature cable failure.

It is essential to have a comprehensive understanding of the manufacturer's specifications regarding cable flexibility and bending radius.

This knowledge plays a vital role in ensuring the safe and reliable operation of robots.

4. Routing and cable organization:

In the realm of robotics, efficient cable management, and routing play a crucial role in maintaining a well-organized and tidy system.

It is essential to ensure proper cable routing to prevent tangling, entanglement in moving parts, and any restrictions on the robot's range of motion.

The use of cable carriers, brackets, and conduits can effectively guide and protect cables, reducing the risk of wear and tear.

By implementing appropriate cable management practices, the overall longevity and functionality of the robotic system can be enhanced.

5. Managing stress:

Robot cables experience a range of stresses, including tension, compression, torsion, and abrasion.

It is crucial to have a clear understanding of the specific stress factors associated with the application and take appropriate measures to support and relieve strain on the cables.

Employing stress relief mechanisms like cable glands, strain relief connectors, and cable tracks can effectively alleviate tension and prevent premature cable failure.

By effectively managing mechanical stress, the lifespan of robot cables can be significantly extended.

6. Regular upkeep and repairs:

Maintaining and repairing robot cables is crucial for their longevity and sustained performance.

Over time, these cables are susceptible to wear and tear, making periodic inspection, maintenance, and possible replacement necessary.

By consistently monitoring the condition of the cables and promptly addressing any signs of damage, unexpected downtime can be avoided, and the robot can continue to operate at its optimal level of performance.

7. Standardisation:

Ensuring compatibility between robot cables and connectors is of utmost importance to ensure smooth integration into robotic systems.

Adhering to industry standards and specifications, such as those established by the Robotic Industries Association (RIA), is essential.

Following these standards helps ensure interoperability and simplifies the process of selecting appropriate cables and connectors that are compatible with the system.

By adhering to compatibility guidelines and industry standards, seamless integration and optimal performance of robot cables can be achieved.

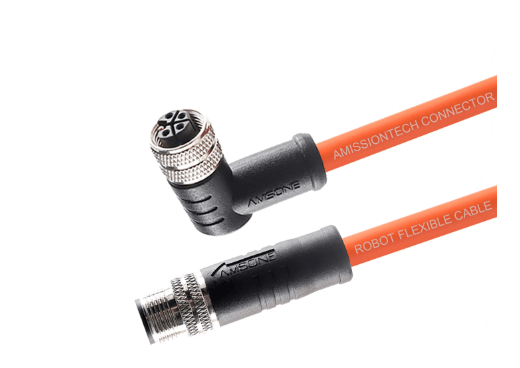

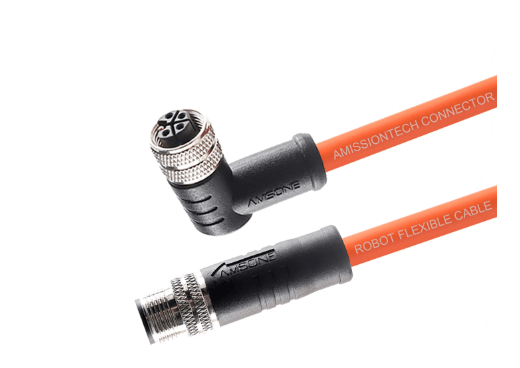

Upgrade your robot cables today and unleash peak performance!

Experience the difference with high-quality robot cables engineered for reliability and efficiency. Don't settle for subpar connections - get the best robot cables to power your innovations!

EN

EN DE

DE JP

JP ES

ES SE

SE FR

FR IT

IT CN

CN 한국어

한국어 ภาษาไทย

ภาษาไทย بالعربية

بالعربية Nederlands

Nederlands Türkçe

Türkçe Język polski

Język polski Tiếng Việt

Tiếng Việt Zulu

Zulu Bahasa Malay

Bahasa Malay