The Importance of Proper Installation and Maintenance of Fieldbus Cables and Connectors

Views: 2936

Author: Site Editor

Publish Time: 2023-10-11

Origin: Site

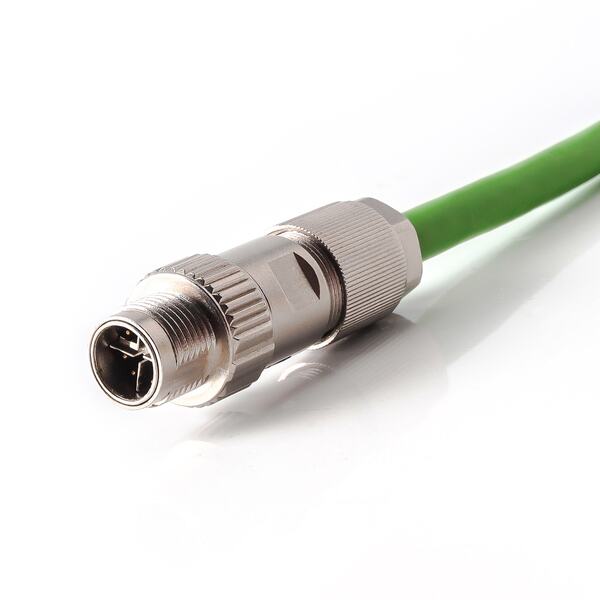

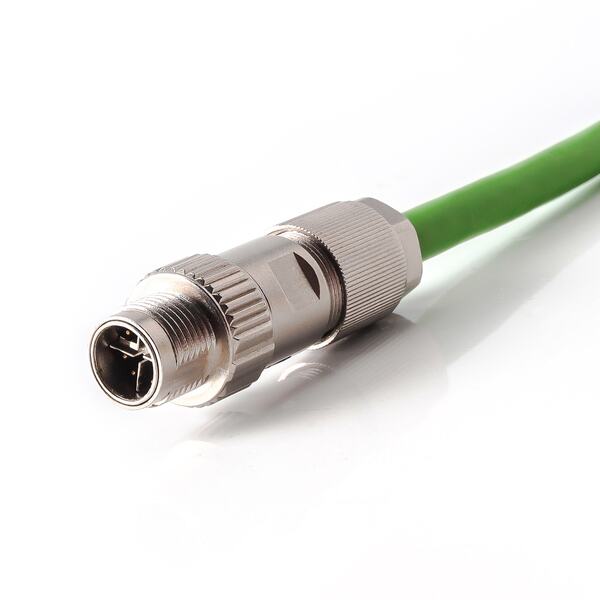

In the realm of industrial automation and process control, Fieldbus systems have become the lifeblood of modern manufacturing. These systems rely on robust Fieldbus cables and connectors to ensure seamless communication between devices. However, the significance of proper installation and regular maintenance of these vital components cannot be overstated. In this article, we'll explore why the correct handling of Fieldbus cables and connectors is crucial for the reliability and performance of industrial operations.

Ensuring Seamless Communication

Fieldbus systems are the nerve center of automation processes, responsible for transmitting data between sensors, controllers, and actuators. Properly installed and maintained Fieldbus cables and connectors ensure uninterrupted communication, preventing data loss or signal interference. Any disruption in communication can lead to costly downtime and production inefficiencies.

Preventing Signal Degradation

Fieldbus cables are designed to carry digital signals over long distances. However, these signals can be susceptible to noise and attenuation if cables are not installed correctly or if connectors are damaged. Proper installation techniques and regular maintenance help prevent signal degradation, ensuring the integrity of data transmission.

Extending Equipment Lifespan

Industrial environments can be harsh, subjecting cables and connectors to extreme temperatures, moisture, and physical stress. Regular maintenance, such as cleaning and inspection, helps identify and address potential issues before they lead to equipment failure. This proactive approach can significantly extend the lifespan of Fieldbus components and reduce replacement costs.

Minimizing Downtime

When Fieldbus cables or connectors fail, it can result in costly production downtime. Proper installation practices, including cable routing and strain relief, can reduce the risk of cable damage or connector failure. Regular maintenance helps detect and address issues early, preventing unexpected outages and minimizing production disruptions.

Ensuring Safety Compliance

In many industrial settings, safety regulations and standards must be met. Proper installation and maintenance of Fieldbus cables and connectors are essential for compliance with these regulations. Neglecting these critical components can lead to safety violations and legal consequences.

Enhancing Data Integrity

Data accuracy is paramount in industrial automation. Fieldbus systems rely on precise data transmission for control and monitoring. Properly installed and maintained cables and connectors contribute to data integrity, ensuring that decisions based on this data are accurate and reliable.

Amissiontech: Your Partner in Fieldbus Solutions

Fieldbus cables and connectors cannot be overstated. These components are the backbone of efficient and reliable data communication in industrial processes. Neglecting their installation and upkeep can result in costly downtime, reduced equipment lifespan, and safety compliance issues.

At Amissiontech, we understand the critical role that Fieldbus cables and connectors play in industrial automation. Our commitment to quality and expertise in the field ensures that our customers receive top-notch solutions. Contact us today to discover how our Fieldbus products and services can help you achieve seamless communication and optimal performance in your industrial operations. Choose Amissiontech for excellence in Fieldbus solutions.

EN

EN DE

DE JP

JP ES

ES SE

SE FR

FR IT

IT CN

CN 한국어

한국어 ภาษาไทย

ภาษาไทย بالعربية

بالعربية Nederlands

Nederlands Türkçe

Türkçe Język polski

Język polski Tiếng Việt

Tiếng Việt Zulu

Zulu Bahasa Malay

Bahasa Malay