Products

I/O Systems

-

IO Link Hub NPN 0.5A/channel Plastic Housing Plastic Thread LockingView All

IO Link Hub NPN 0.5A/channel Plastic Housing Plastic Thread LockingView All -

P/N: ALD-HBN1-354XXX

IO Link Hub NPN 0.5A/channel Metal Housing Metal Thread / Bayonet LockingView All -

P/N: ALD-HBN1-310XXX

IO Link Hub NPN 0.5A/channel Metal Housing Metal Thread LockingView All -

P/N: ALD-HBP1-372XXX

IO Link Hub PNP 2A/channel Plastic Housing Plastic Thread LockingView All -

P/N: ALD-HBP2-364XXX

IO Link Hub PNP 2A/channel Plastic Housing Metal Thread/Bayonet LockingView All -

P/N: ALD-HBP1-372XXX

IO Link Hub PNP 0.5A/channel Plastic Housing Plastic Thread LockingView All -

P/N: ALD-HBP1-351XXX

IO Link Hub PNP 0.5A/channel Plastic Housing Metal Thread/Bayonet LockingView All -

P/N: ALD-HBP2-330XXX

IO Link Hub PNP 2A/channel Metal Housing Metal Thread LockingView All

-

P/N: ALM-MPA1-051XXX

IO Link Master Multiprotocol Plastic Housing 7/8 Power ConnectorView All -

P/N: ALM-ECA1-010XXX

IO Link Master EtherCAT Single ProtocolView All -

P/N: ALM-MPA1-041XXX

IO Link Master Multiprotocol Plastic Housing M12 L-Codedd Power ConnectorView All -

P/N: ALM-MPA1-030XXX

IO Link Master Multiprotocol Metal Housing M12 L-Codedd Power ConnectorView All -

P/N: ALM-PNA1-010XXX

IO Link Master Profitnet Single ProtocolView All

Circular Connectors

-

P/N: AM08M0411AXX1-XXX

M8 4Pin Pre-molded Cable Male Straight M8 ConnectorView All -

P/N: AM08F0822A001

M8 Device Connector Panel Rear Mount M8 8P Female ReceptacleView All -

P/N: AM08M0622A001

M8 Device Connector Panel Rear Mount M8 6P Male ReceptacleView All -

P/N: AM08M0811AXX1-XXX

M8 8Pin Pre-molded Cable Male Straight M8 ConnectorView All -

P/N: AM08M0822A003

M8 Device Connector Male 8Pin PCB Receptacle Panel Rear Mount Right Angled ShieldedView All -

P/N: AM08M0822A001

M8 Device Connector Panel Rear Mount M8 8P Male ReceptacleView All -

P/N: AM08F0811AXX3-XXX

M8 8P Female Shield Connector Pre-molded Cable Right Angled IP67View All -

P/N: AM08M0811AXX3-XXX

M8 Connector 8P Male Shield Pre-molded Cable Right Angled IP67View All

-

P/N: AM12F1211AXX1-XXX

M12 pre-molded cable connector, female, contacts: 12,solder connection, A code, straight, IP67View All -

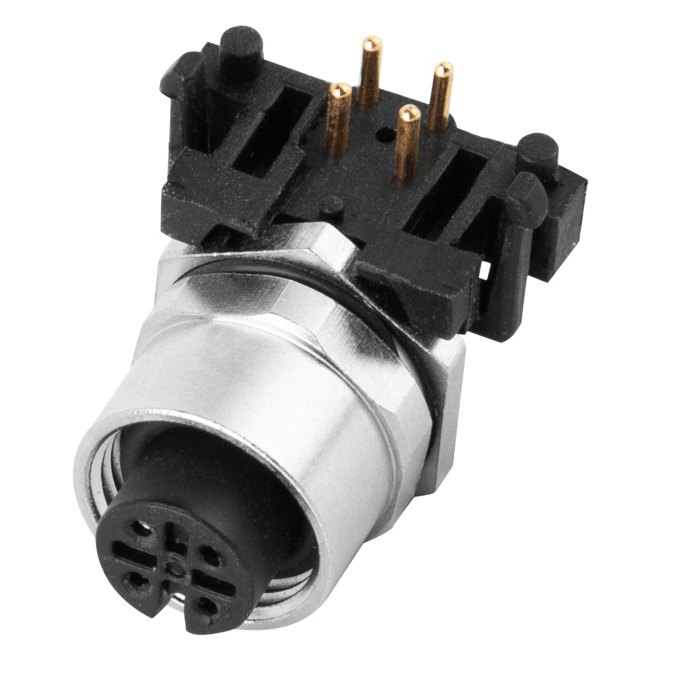

P/N: AM12F0822A005

M12 panel receptacle, rear mount, female, contacts: 8, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12F0522A005

M12 panel receptacle, rear mount, female, contacts: 5, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12F0512AXX1-XXX

M12 panel receptacle, rear mount, female, contacts: 5, solder connection for wires, A code, straight, IP67View All -

P/N: AM12M0422A005

M12 panel receptacle, rear mount, male, contacts: 4, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12M0522A005

M12 panel receptacle, rear mount, male, contacts: 5, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12F0534A007

M12 cable connector, female, contacts:5, field assembly type, screw connection, A code, right angled, IP67View All -

P/N: AM12M0822A005

M12 panel receptacle, rear mount, male, contacts: 8, PCB dip-solder connection, A code, right angled, IP67View All

-

P/N: AM12F0522B001

M12 panel receptacle, rear mount, female, contacts:5, solder connection, B code, straight, IP67View All -

P/N: AM12M0522B001

M12 B Code Male Panel Rear Mount Receptacle PCB Connector PG9View All -

P/N: AM12F0511BXX1-XXX

M12 pre-molded cable connector, female, contacts:5, solder connection, B code, straight, IP67View All -

P/N: AM12M0511BXX1-XXX

M12 pre-molded cable connector, male, contacts:5, solder connection, B code, straight, IP67View All -

P/N: AM12F0422B001

M12 panel receptacle, rear mount, female, contacts:4, PCB dip-solder connection, B code, straight, IP67View All -

P/N: AM12M0422B001

M12 panel receptacle, rear mount, male, contacts:4, PCB dip-solder connection, B code, straight, IP67View All -

P/N: AM12M0512B002

M12 5P Male B Code Panel Rear Mount Receptacle Wires Solder Connector M16*1.5View All -

P/N: AM12M0512B001

M12 5P Male B Code Panel Rear Mount Receptacle Wires Solder Connector PG9View All

-

P/N: AM12F0422D006

M12 panel receptacle, rear mount, female, contacts:4, PCB dip-solder connection, D code, right angled, IP67View All -

P/N: AM12M0412D001

M12 D Code Male Panel Rear Mount Receptacle For Wires Solder Connector PG9View All -

P/N: AM12F0413D001

M12 panel receptacle, front mount, female, contacts:4, solder connection for wires, D code, straight, IP67View All -

P/N: AM12M0413D351-005

M12 Panel Receptacle Front Mount Male 4Pin Solder Connection For Wires D Code Straight IP67View All -

P/N: AM12F0422D001

M12 panel receptacle, rear mount, female, contacts:4, PCB dip-solder connection, D code, straight, IP67View All -

P/N: AM12M0422D001

M12 panel receptacle, rear mount, male, contacts:4, PCB dip-solder connection, D code, straight, IP67View All -

P/N: AM12F0411D241-010

M12 4P D Code Pre-molded Cable Connector Female Straight IP67View All -

P/N: AM12M0411D241-010

M12 pre-molded cable connector male solder connection D code straight IP67View All

-

P/N: AM12F0822X008

M12 X Code 8Pole Panel Receptacle Rear Mount Female PCB Dip-solder Connection Right Angled IP67View All -

P/N: AM12M0822X001

M12 Panel Receptacle Rear Mount Male PCB DIP Solder X Code StraightView All -

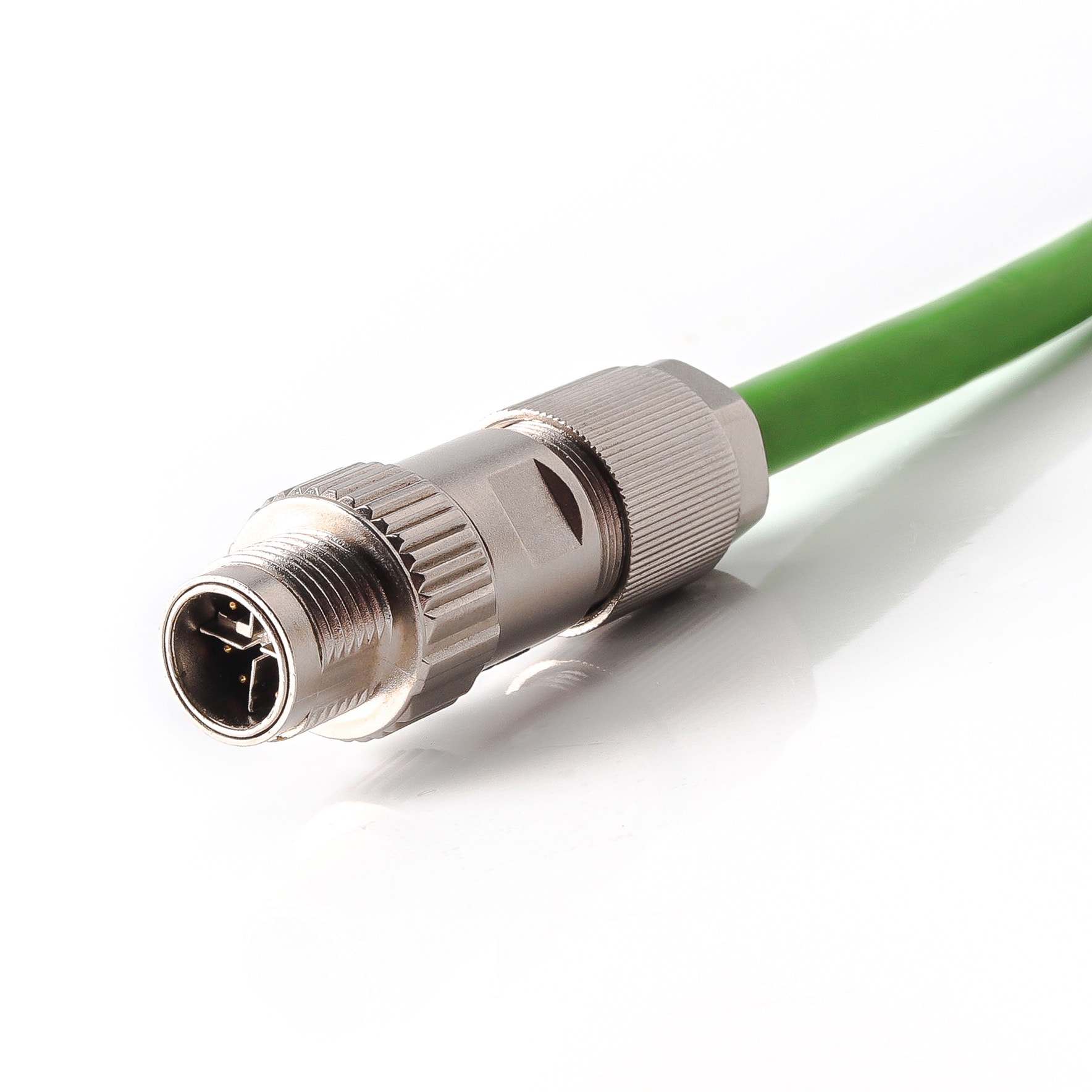

P/N: AM12M0811X003

M12 data cable connector, contact: 8P, male, for pre-molding , X code, straight, 360 EMC shielding, solder connection, 0.5A/60VView All -

P/N: AM12M0844X003

M12 X Code Field Assembly Connector Male EMC Shielded Straight IP67 Crimp ContactsView All -

P/N: AM12M0811X233-100

M12 Pre-molded Cable Connector 8Pole Male X Code EMC Profinet/Ethernet Cable StraightView All -

P/N: AM12F0822X002

M12 X Code Receptacle Panel Rear Mount Female PCB DIP Connection M16*1.5View All -

P/N: AM12F0822X001

M12 X Code Receptacle Panel Rear Mount Female PCB DIP Connection PG9View All -

P/N: AM12F0812X001

M12 X Code Receptacle Panel Rear Mount Female For Solder Wires ConnectionView All

-

P/N: AM12F0822Y002

M12 Hybrid Connector,Y Code,Female,Panel Mount Receptacle,M12 Device ConnectorView All -

P/N: AM12M0822Y002

M12 Hybrid Connector,Y Code,Male,Panel Mount Receptacle,M12 Device ConnectorView All -

P/N: AM12M0811YXX1-XXX

M12 Hybrid Connector,Male,M12 Y-Coded Power Signal Ethernet CableView All -

P/N: AM12F0811YXX1-XXX

M12 Hybrid Connector,Female,Power Signal,M12 Y-Coded CablesView All -

P/N: AM12F0812Y003

M12 Hybrid Connector,Female,Panel Mount Shielded,M12 Y-CodedView All

-

P/N: AM12F0434T001

M12 cable connector, female, contacts: 4, field assembly type, screw connection, T code, straight, IP67View All -

P/N: AM12M0434T001

M12 cable connector, male, contacts: ,4, field assembly type, screw connection, T code, straight, IP67View All -

P/N: AM12F0412T171 -XXX

M12 panel receptacle, female, contacts: 4, solder connection for wires, T code, straight, IP67View All -

P/N: AM12M0412T171-XXX

M12 panel receptacle, male, contacts: 4, solder connection for wires, T code, straight, IP67View All -

P/N: AM12F0322T001

M12 panel receptacle, female, contacts: 3,PCB dip-solder connection, T code, straight, IP67View All -

P/N: AM12M0322T001

M12 panel receptacle, male, contacts: 3,PCB dip-solder connection, T code, straight, IP67View All -

P/N: AM12F0311TXX1-XXX

M12 pre-molded cable connector, female, contacts: 3,solder connection, T code, straight, IP67View All -

P/N: AM12M0311TXX1-XXX

M12 pre-molded cable connector, male, contacts:3, solder connection, T code, straight, IP67View All

-

P/N: AM12F0411SXX1-XXX

M12 pre-molded cable connector, female, contacts:4(3+PE), solder connection, S code, straight, IP67View All -

P/N: AM12M0322S001

M12 panel receptacle, rear mount, male, contacts:3(2+PE),PCB dip-solder connection, S code, straight, IP67View All -

P/N: AM12F0412S171-XXX

M12 panel receptacle, rear mount, female, contacts:4, solder connection for wires, S code, straight, IP67View All -

P/N: AM12M0412S171-XXX

M12 panel receptacle, rear mount, male, contacts:4, solder connection for wires, S code, straight, IP67View All -

P/N: AM12F0322S001

M12 panel receptacle, rear mount, female, contacts:3(2+PE),PCB dip-solder connection, S code, straight, IP67View All -

P/N: AM12M0422S001

M12 panel receptacle, rear mount, male, contacts:,4(3+PE), PCB dip-solder connection, S code, straight, IP67View All -

P/N: AM12F0311SXX1-XXX

M12 pre-molded cable connector, female, contacts:3(2+PE), solder connection, S code, straight, IP67View All -

P/N: AM12F0322S002

M12 panel receptacle, rear mount, female, contacts:3(2+PE), PCB dip-solder connection, S code, straight, IP67View All

-

P/N: AM12M0511Lxx1-xxx

M12 L Coded Power 5P Connector Male Drag Chain Pre-Molded CableView All -

P/N: AM12M0412L171-XXX

M12 panel receptacle, rear mount, male, contacts:4, solder connection for wires, L code, straight, IP67View All -

P/N: AM12M0522L001

M12 panel receptacle, rear mount, male, contacts:5, PCB dip-solder connection, L code, straight, IP67View All -

P/N: AM12F0411LXX2-XXX

M12 pre-molded cable connector, female, contacts:4, solder connection, L code, straight, IP67View All -

P/N: AM12M0411LXX1-XXX

M12 pre-molded cable connector, male, contacts:4, solder connection, L code, straight, IP67View All -

P/N: AM12M0322L001

M12 panel receptacle, rear mount, male, contacts:3, PCB dip-solder connection, L code, straight, IP67View All -

P/N: AM12M0422L001

M12 panel receptacle, rear mount, male, contacts:4,PCB dip-solder connection, L code, straight, IP67View All -

P/N: AM12F0311LXX1-XXX

M12 pre-molded cable connector, female, contacts:3, solder connection, L code, straight, IP67View All

-

P/N: AM12M0312K171-XXX

M12 panel receptacle, rear mount, male, contacts:3,solder connection for wires, K code, straight, IP67View All -

P/N: AM12F0522K001

M12 panel receptacle, rear mount, female, contacts:5, PCB dip-solder connection, K code, straight, IP67View All -

P/N: AM12M0522K001

M12 panel receptacle, rear mount, male, contacts:5,PCB dip-solderconnection, K code, straight, IP67View All -

P/N: AM12F0311KXX1-XXX

M12 pre-molded cable connector, female, contacts:3, solder connection, K code, straight, IP67View All -

P/N: AM12M0311KXX1-XXX

M12 pre-molded cable connector, male, contacts:3, solder connection, K code, straight, IP67View All -

P/N: AM12F0513K371-005

M12 K Code 5P(4+PE) Female Panel Front Mount Receptacle ConnectorView All -

P/N: AM12F0312K171-XXX

M12 panel receptacle, rear mount, female, contacts:3, solder connection for wires, K code, straight, IP67View All

-

P/N: AM12M0512M371-XXX

M12 Device Receptacle M Code Panel Rear Mount Male 5Pin Connector For WiresView All -

P/N: AM12F0322M001

M12 Device Receptacle M Code Panel Rear Mount Female 3Pin PCB ConnectorView All -

P/N: AM12F0612M171-XXX

M12 Device Receptacle M Code Panel Rear Mount Female 6Pin Connector For WiresView All -

P/N: AM12M0612M371-XXX

M12 Device Receptacle M Code Panel Rear Mount Male 6Pin Connector For WiresView All -

P/N: AM12M0522M001

M12 Device Receptacle M Code Panel Rear Mount Male 5Pin PCB ConnectorView All -

P/N: AM12F0611MXX1-XXX

M12 M Code 5+PE Pre-molded Cable 6Pin Female Straight ConnectorView All -

P/N: AM12M0611MXX1-XXX

M12 M Code 5+PE Pre-molded Cable 6Pin Male Straight ConnectorView All -

P/N: AM12F0522M001

M12 Device Receptacle M Code Panel Rear Mount Female 5Pin PCB ConnectorView All

-

P/N: AM09F0522A001

M9 Connector Receptacle Panel Rear Mount Female 5Pole PCB Dip-solderView All -

P/N: AM09F0411A001

M9 pre-molded cable connector, female, contacts:4, solder connection, straight, IP67View All -

P/N: AM09F0311A001

M9 pre-molded cable connector, female, contacts: 3, solder connection, straight, IP67View All -

P/N: AM09F0822A001

M9 Female Panel Rear Mount Receptacle 8Pin PCB Waterproof ConnectorView All -

P/N: AM09F0422A001

M9 4P Female Panel Rear Mount Receptacle PCB Waterproof ConnectorView All -

P/N: AM09F0322A001

M9 3Pole Female Panel Rear Mount Receptacle PCB Waterproof ConnectorView All -

P/N: AM09F0522A201

M9 Female Panel Rear Mount Receptacle 5Pin PCB Connector Right AngledView All

-

P/N: AM16F2422A001

M16 panel receptacle,rear mount,Female, contacts:24, PCB dip- solder connection,straight,IP67,UL certifiedView All -

P/N: AM16M2422A001

M16 panel receptacle,rear mount,male, contacts:24, PCB dip- solder connection,straight,IP67,UL certifiedView All -

P/N: AM16F2411AXX2-XXX

M16 pre-molded cable connector, female, contacts:24, solder connection, right angled, IP67, shieldable, UL certifiedView All -

P/N: AM16M0522B001

M1M16 panel receptacle, rear mount, male, contacts:5, PCB dip-solderconnection, straight, IP67, UL certifiedView All -

P/N: AM16F1222A001

M16 panel receptacle, rear mount, female, contacts:12,PCB connection, straight, IP67, UL certifiedView All -

P/N: AM16M1222A001

M16 panel receptacle, rear mount, male, contacts:12,PCB dip-solder connection, straight, IP67, UL certifiedView All -

P/N: AM16M2411AXX1-XXX

M16 pre-molded cable connector, male, contacts:24, solder connection, straight, IP67, shieldableView All -

P/N: AM16M1214A001

M16 cable connector, male, contacts:12,field assembly type, solder connection, straight, IP67, UL certifiedView All

-

P/N: AM78F0511A162-010

MINI-Change 7/8View All -

P/N: AM78M0522A001

MINI-Change 7/8-16UNF Panel Rear Mount Receptacle Male 5Pin PCB ConnectorView All -

P/N: AM78F0412A371-050

7/8View All -

P/N: AM78M0412A371-050

7/8View All -

P/N: AM78F0512A371-050

7/8View All -

P/N: AM78M0512A371-050

7/8View All -

P/N: AM78F0312A371-050

7/8View All -

P/N: AM78M0312A371-050

7/8View All

-

P/N: AM23M1912A002

M23 Panel Receptacle Rear Mount Male 19P(16+3) Solder Connection For Wires Straight IP67View All -

P/N: AM23F1911AXX1-XXX

M23 Pre-molded Cable Connector Female 19P(16+3) Solder Connection Straight IP67View All -

P/N: AM23M1911AXX1-XXX

M23 Pre-molded Cable Connector Male 19P(16+3) Solder Connection Straight IP67View All

-

P/N: BM24F0212A001

Bayonet Connector BM24 2P Receptacle Panel Mount Solder ConnectView All -

P/N: BM24M0214A001

Bayonet Connector BM24 2P Plug Connector Field InstallationView All -

P/N: BM24M0314A001

Bayonet Connector BM24 3P Plug Connector Field InstallationView All -

P/N: BM24F0312A001

Bayonet Connector BM24 3P Receptacle Panel Mount Solder ConnectView All -

P/N: BM24M0414A001

Bayonet Connector BM24 4P Plug Connector Field InstallationView All -

P/N: BM24F0412A001

Bayonet Connector BM24 4P Receptacle Panel Mount Solder ConnectView All -

P/N: BM24M1214A001

Bayonet Connector BM24 12P Plug Connector Field InstallationView All -

P/N: BM24F1222A001

Bayonet Connector BM24 12P Receptacle Panel Mount PCB ConnectView All

Industrial Cable Harnesses

-

P/N: AM12F0411D241-010

M12 4P D Code Pre-molded Cable Connector Female Straight IP67View All -

P/N: AM12M0411D241-010

M12 pre-molded cable connector male solder connection D code straight IP67View All -

P/N: AM12F0812X003

M12 Device Connector X Code Female EMC Shielded Panel Rear Mount ReceptacleView All -

P/N: AM12M0811X231-030

M12 Pre-molded Cable Connector 8Pole Male X Code Cable StraightView All -

P/N: AM12F0411BXX1-XXX

M12 pre-molded cable connector, female, contacts:4, solder connection, B code, straight, IP67View All -

P/N: AM12F0511A241-010

M12 FieldBUS Cable Industrial Automation DeviceNet CanOpen CableView All -

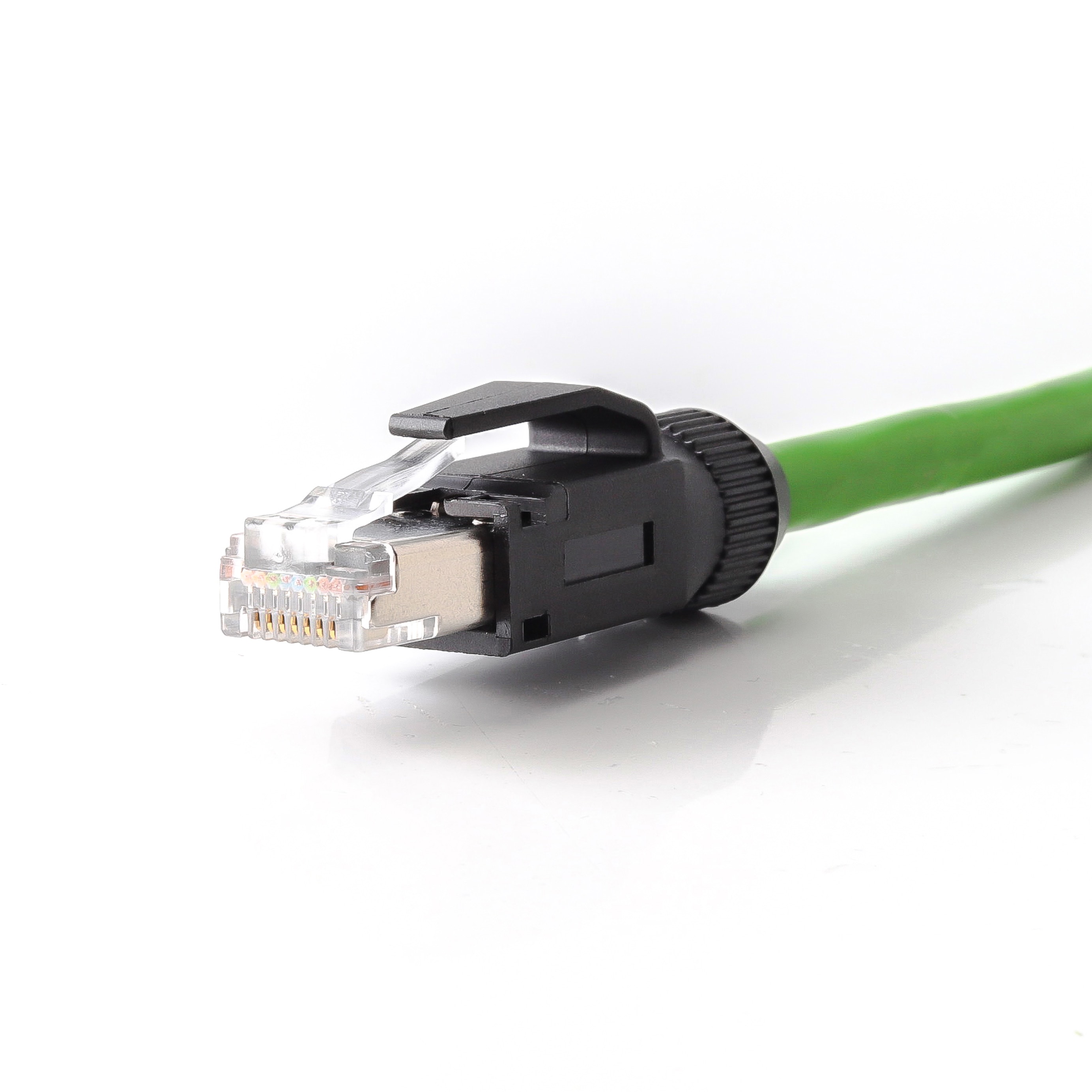

P/N: EhterNet Cable

EhterNet Cable CAT5/CAT6/CAT7 PROFIBUS Industrial Network cableView All -

P/N: AM12M0814X221-010

M12 X Code Male ProfiNET/EtherNET Cable M12 Connector X CodedView All

-

P/N: AM12F0411D241-010

M12 4P D Code Pre-molded Cable Connector Female Straight IP67View All -

P/N: AM78M0411A272-050

DeviceNET 7/8View All -

P/N: AM12F0411BXX1-XXX

M12 pre-molded cable connector, female, contacts:4, solder connection, B code, straight, IP67View All -

P/N: AM12F0511A241-010

M12 FieldBUS Cable Industrial Automation DeviceNet CanOpen CableView All -

P/N: AM78M0511A172-030

MINI-Change 7/8View All

-

P/N: AM12M0411D241-010

M12 pre-molded cable connector male solder connection D code straight IP67View All -

P/N: AM12F0812X003

M12 Device Connector X Code Female EMC Shielded Panel Rear Mount ReceptacleView All -

P/N: AM12M0811X231-030

M12 Pre-molded Cable Connector 8Pole Male X Code Cable StraightView All -

P/N: EhterNet Cable

EhterNet Cable CAT5/CAT6/CAT7 PROFIBUS Industrial Network cableView All -

P/N: AM12M0811YXX1-XXX

M12 Hybrid Connector,Male,M12 Y-Coded Power Signal Ethernet CableView All -

P/N: AM12F0811YXX1-XXX

M12 Hybrid Connector,Female,Power Signal,M12 Y-Coded CablesView All -

P/N: AM12F0812Y003

M12 Hybrid Connector,Female,Panel Mount Shielded,M12 Y-CodedView All

-

P/N: AM78H0511A433-XXX

Electrical Automation Power Supply Connector Cable 7/8-16UNF Pre-molded H-SplitterView All -

P/N: AM12H0811AXX1-XXX

M12 A Code 8P/4P Connector Y-Splitter Industrial Automation Sensor CableView All -

P/N: AM08Y0411A001-000

M8 Y-Splitter Electrical Automation Sensor Connector AdapterView All

Underwater Connectors and Cables

-

P/N: RMK5F

RMK5F 2, 3, 4, 5, 6 And 8 Contacts Deepsea Watertight ConnectorsView All -

P/N: MCDLS-F

MCDLS-F 2, 3, 4, 5, 6 and 8 contacts Deepsea Watertight ConnectorsView All -

P/N: MCBH5MTI

MCBH5MTI 2, 3, 4, 5, 6 And 8 Contacts Deepsea Watertight ConnectorsView All -

P/N: HPBH9M

HPBH9M 9 Contacts Deepsea Watertight ConnectorsView All -

P/N: HF75 50CXBH6F

HF75 50CXBH6F 6 Contacts Deepsea Watertight ConnectorsView All -

P/N: DMCIL13F M

DMCIL13F M 13 contacts Underwater cable connectorView All -

P/N: AWQ7-42

AWQ7-42 24, 28, 32, 36, 42 contacts Underwater cable connectorView All -

P/N: 1L25F M

1L25F M Circular 12, 16, 25 Contacts Underwater ConnectorView All

company

News

-

Amissiontech to Showcase Smart Interconnection Solutions at SPS 2025 in NurembergView All

Amissiontech to Showcase Smart Interconnection Solutions at SPS 2025 in NurembergView All -

2025 Tokyo International Manufacturing Expo: A Perfect ConclusionView All

2025 Tokyo International Manufacturing Expo: A Perfect ConclusionView All -

Amissiontech to Showcase Advanced Industrial Connectors and I/O Solutions at Manufacturing World Japan 2025View All

Amissiontech to Showcase Advanced Industrial Connectors and I/O Solutions at Manufacturing World Japan 2025View All -

Amissiontech Reflects on a Successful Participation at ProPak China 2025View All

Amissiontech Reflects on a Successful Participation at ProPak China 2025View All -

Amissiontech Team-Building Activity at Hailing IslandView All

Amissiontech Team-Building Activity at Hailing IslandView All -

Dragon Boat Festival Greetings: Celebrating Tradition with AmissiontechView All

Dragon Boat Festival Greetings: Celebrating Tradition with AmissiontechView All -

Celebrating Women at Amissiontech on International Women’s DayView All

Celebrating Women at Amissiontech on International Women’s DayView All -

Amissiontech Invites You to HANNOVER MESSE 2025View All

Amissiontech Invites You to HANNOVER MESSE 2025View All

-

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All -

What is an M12 A coded connector?View All

What is an M12 A coded connector?View All -

What Do You Know M12 B Coded?View All

What Do You Know M12 B Coded?View All -

Revolutionizing Field I/O Signal Transmission with Amissiontech's IO-Link HUBView All

Revolutionizing Field I/O Signal Transmission with Amissiontech's IO-Link HUBView All -

Exploring the Technology Behind Underwater Connectors and CablesView All

Exploring the Technology Behind Underwater Connectors and CablesView All -

Amissiontech's IO-LINK Modules Shine at HANNOVER MESSE 2024View All

Amissiontech's IO-LINK Modules Shine at HANNOVER MESSE 2024View All -

Circular ConnectorView All

Circular ConnectorView All -

IO-Link Module - Connects Future Digital CommunicationsView All

IO-Link Module - Connects Future Digital CommunicationsView All

-

Understanding Ethernet MHz Speed and Its Impact on Network PerformanceView All

Understanding Ethernet MHz Speed and Its Impact on Network PerformanceView All -

Top 10 Cable Types and Their UsesView All

Top 10 Cable Types and Their UsesView All -

HDMI vs VGA: Understanding the Key Differences for Industrial & Custom Cable ApplicationsView All

HDMI vs VGA: Understanding the Key Differences for Industrial & Custom Cable ApplicationsView All -

Complete Guide to Ethernet Cable CategoriesView All

Complete Guide to Ethernet Cable CategoriesView All -

Wire Harness Production ExplainedView All

Wire Harness Production ExplainedView All -

Industrial HDMI Shielded Cable Technology InterpretationView All

Industrial HDMI Shielded Cable Technology InterpretationView All -

Revolutionize Automation with DeviceNet-Compatible ToolsView All

Revolutionize Automation with DeviceNet-Compatible ToolsView All -

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All

Industries and Solutions

Solutions

Industries

News And Events

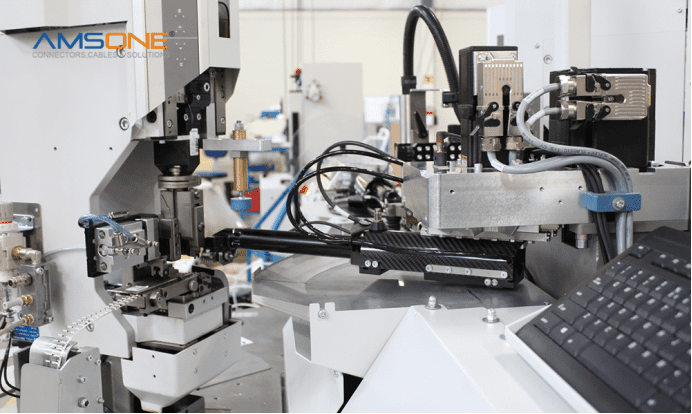

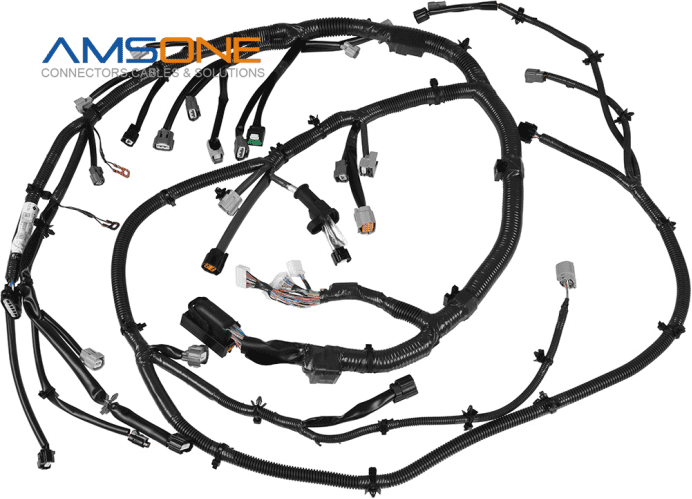

Automation or Handmade for Cable Harness Assembly?

In the modern manufacturing landscape, automation is prevalent, yet certain functions demand human experience and expertise. Just as doctors care for patients aided by technology and engineers design roads using computer software, complex wire harnesses require the same level of engineering and expertise. In this special edition of AMSONE, we explore why full automation is unsuitable for complex wire harnesses, covering the following topics:

Unraveling Complex Wire Harnesses:

Precision engineering and assembly are essential for complex wire harness designs, surpassing what automation can achieve. Wire harnesses consist of an outer protective sheath (often thermoplastic) and inner wires or cables, utilizing materials like PVC, Teflon®, and Silicone. They offer a cost-effective electrical solution, but some projects demand intricate designs with conductors, connectors, terminations, overmolds, grommets, and strain relief. These complexities necessitate expertise and engineering, a specialty provided by AMSONE.

The Human Engineering Aspect:

Each project receives individual attention, and our design team's tested expertise ensures custom wire harness designs with minimal pitfalls. While automation plays a role, design iterations and rigorous testing are done manually to guarantee safe and proper functioning. AMSONE's commitment to quality ensures no product leaves our production line without thorough examination.

Aspects Suitable for Automation:

According to a research paper by Siemens Digital, fully automated complex wire harness design offers various benefits, including faster engineering and validation, streamlined production design, automated change management, and more. While it may seem cost-effective initially, engineering and careful product testing ensure long-term economic benefits and improved product quality. Sacrificing quality for speed and cost may not be a wise choice, and a balanced approach that includes expertise and engineering is recommended for wire harness design.

The Human Touch in Assembly:

While computer drafting software aids the initial engineering process, full automation is not recommended to ensure the design matches the project. AMSONE specializes in custom solutions, designing over 70% of the products we produce. The final testing phase should also avoid full automation as it requires experience and expertise for the highest quality wire harnesses. Certain manufacturing processes, like incorporating wires of different lengths or performing multiple crimps on a single wire, should not be automated. AMSONE Cable possesses over 5,000 existing tools, using the right ones for various project applications, ensuring complex wire harnesses are manufactured with expertise and precision.

Uniqueness in Design Features:

Wire harness design features offer a range of options for customization, ensuring the perfect fit for each project. Conductor sizes span from 12 AWG to 34 AWG, while conductor colors can be tailored for effective wire management. Stranding sizes from 0.002" to 0.01" match various applications, and choices for conductor insulation materials, such as PVC and Teflon®, cater to project needs. AMSONE uses UL® certified cables and wires, ensuring a safe and reliable product from the start.

In conclusion, while automation has undoubtedly transformed manufacturing, the world of complex wire harnesses remains an arena where human engineering and expertise continue to shine. Recognizing the delicate balance between automation and human involvement is key to unlocking the full potential of this critical technology.

The Industrial Control System Cable Harness:

Industrial control systems encompass various technical aspects, connecting devices and systems to automate processes. Found in diverse industries like water treatment and bottling facilities, these systems rely on cable assemblies to transmit data, signals, and power effectively. With the increasing demand for automation, AMSONE excels in designing custom cable assemblies and wire harnesses, emphasizing unparalleled quality and expertise. Our advanced capabilities ensure the production of industrial cable assemblies that enable sophisticated industrial processes worldwide.

Wire Assemblies for Medical Equipment:

Medical wire assemblies are essential components in various medical equipment, serving as data transmitters, power links, and communication mediums. AMSONE specializes in custom-built, highly reliable medical wire assemblies for critical medical applications. With UL-certified components and expertise in working with materials like Teflon and Silicone, AMSONE ensures precise and high-quality cable assemblies. These assemblies are designed to transmit medical data and power equipment and operate reliably in crucial circumstances. As a top priority, proper functionality is crucial to aid patients accurately. Contact AMSONE Cable to learn more about our custom medical wire assemblies crafted with precision and quality standards.

Cable Assemblies for Telecommunication:

The world heavily relies on telecommunications infrastructure for seamless connectivity, from airplanes to tablets. As globalization increases, the demand for high-quality, reliable cable assemblies for telecom applications grows steadily. AMSONE excels in crafting cable assemblies for telecommunications, starting with single-strand conductors and utilizing state-of-the-art facilities for extrusion. With expertise in connectors, terminations, sheathing, and harnesses, our engineering staff creates perfect cable assemblies for each project, meeting performance, timeline, and budget requirements. Our decades of experience in designing complex cable assemblies for telecommunication equipment allow us to handle increasing data, power, and signal transfer demands. Seamlessly integrating into existing systems is our expertise, providing on-time and on-budget solutions. As a premier telecommunication cable assembly manufacturer, we deliver custom solutions with distinction.

AMSONE Cable: Your Custom Cable Assembly Solution Provider

AMSONE Cable caters to diverse industries like automotive, broadcasting, energy, and more, offering adaptable and customized products. With a vast tool inventory of over 5,000 connectors, junctions, overmolds, and housings, we are likely to have what you need. For over a decade, AMSONE has been a leader in designing and manufacturing cable assemblies for various sectors, including telecommunications, retail security, and industrial controls. Our expertise lies in custom solutions, excelling in product start-up, prototype runs, pre-production testing, and volume manufacturing. Contact AMSONE today for more information.