Products

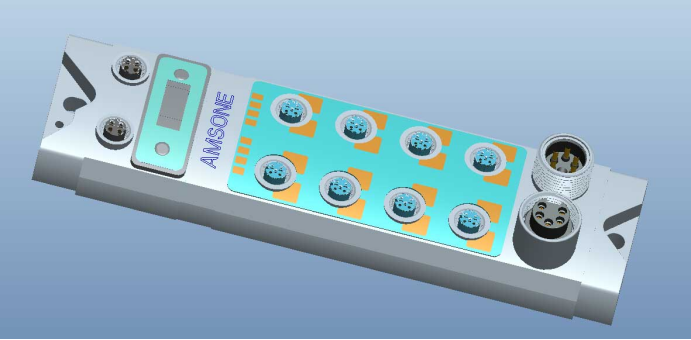

I/O Systems

-

IO Link Hub NPN 0.5A/channel Plastic Housing Plastic Thread LockingView All

IO Link Hub NPN 0.5A/channel Plastic Housing Plastic Thread LockingView All -

P/N: ALD-HBN1-354XXX

IO Link Hub NPN 0.5A/channel Metal Housing Metal Thread / Bayonet LockingView All -

P/N: ALD-HBN1-310XXX

IO Link Hub NPN 0.5A/channel Metal Housing Metal Thread LockingView All -

P/N: ALD-HBP1-372XXX

IO Link Hub PNP 2A/channel Plastic Housing Plastic Thread LockingView All -

P/N: ALD-HBP2-364XXX

IO Link Hub PNP 2A/channel Plastic Housing Metal Thread/Bayonet LockingView All -

P/N: ALD-HBP1-372XXX

IO Link Hub PNP 0.5A/channel Plastic Housing Plastic Thread LockingView All -

P/N: ALD-HBP1-351XXX

IO Link Hub PNP 0.5A/channel Plastic Housing Metal Thread/Bayonet LockingView All -

P/N: ALD-HBP2-330XXX

IO Link Hub PNP 2A/channel Metal Housing Metal Thread LockingView All

-

P/N: ALM-MPA1-051XXX

IO Link Master Multiprotocol Plastic Housing 7/8 Power ConnectorView All -

P/N: ALM-ECA1-010XXX

IO Link Master EtherCAT Single ProtocolView All -

P/N: ALM-MPA1-041XXX

IO Link Master Multiprotocol Plastic Housing M12 L-Codedd Power ConnectorView All -

P/N: ALM-MPA1-030XXX

IO Link Master Multiprotocol Metal Housing M12 L-Codedd Power ConnectorView All -

P/N: ALM-PNA1-010XXX

IO Link Master Profitnet Single ProtocolView All

Circular Connectors

-

P/N: AM08M0411AXX1-XXX

M8 4Pin Pre-molded Cable Male Straight M8 ConnectorView All -

P/N: AM08F0822A001

M8 Device Connector Panel Rear Mount M8 8P Female ReceptacleView All -

P/N: AM08M0622A001

M8 Device Connector Panel Rear Mount M8 6P Male ReceptacleView All -

P/N: AM08M0811AXX1-XXX

M8 8Pin Pre-molded Cable Male Straight M8 ConnectorView All -

P/N: AM08M0822A003

M8 Device Connector Male 8Pin PCB Receptacle Panel Rear Mount Right Angled ShieldedView All -

P/N: AM08M0822A001

M8 Device Connector Panel Rear Mount M8 8P Male ReceptacleView All -

P/N: AM08F0811AXX3-XXX

M8 8P Female Shield Connector Pre-molded Cable Right Angled IP67View All -

P/N: AM08M0811AXX3-XXX

M8 Connector 8P Male Shield Pre-molded Cable Right Angled IP67View All

-

P/N: AM12F1211AXX1-XXX

M12 pre-molded cable connector, female, contacts: 12,solder connection, A code, straight, IP67View All -

P/N: AM12F0822A005

M12 panel receptacle, rear mount, female, contacts: 8, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12F0522A005

M12 panel receptacle, rear mount, female, contacts: 5, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12F0512AXX1-XXX

M12 panel receptacle, rear mount, female, contacts: 5, solder connection for wires, A code, straight, IP67View All -

P/N: AM12M0422A005

M12 panel receptacle, rear mount, male, contacts: 4, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12M0522A005

M12 panel receptacle, rear mount, male, contacts: 5, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12F0534A007

M12 cable connector, female, contacts:5, field assembly type, screw connection, A code, right angled, IP67View All -

P/N: AM12M0822A005

M12 panel receptacle, rear mount, male, contacts: 8, PCB dip-solder connection, A code, right angled, IP67View All

-

P/N: AM12F0522B001

M12 panel receptacle, rear mount, female, contacts:5, solder connection, B code, straight, IP67View All -

P/N: AM12M0522B001

M12 B Code Male Panel Rear Mount Receptacle PCB Connector PG9View All -

P/N: AM12F0511BXX1-XXX

M12 pre-molded cable connector, female, contacts:5, solder connection, B code, straight, IP67View All -

P/N: AM12M0511BXX1-XXX

M12 pre-molded cable connector, male, contacts:5, solder connection, B code, straight, IP67View All -

P/N: AM12F0422B001

M12 panel receptacle, rear mount, female, contacts:4, PCB dip-solder connection, B code, straight, IP67View All -

P/N: AM12M0422B001

M12 panel receptacle, rear mount, male, contacts:4, PCB dip-solder connection, B code, straight, IP67View All -

P/N: AM12M0512B002

M12 5P Male B Code Panel Rear Mount Receptacle Wires Solder Connector M16*1.5View All -

P/N: AM12M0512B001

M12 5P Male B Code Panel Rear Mount Receptacle Wires Solder Connector PG9View All

-

P/N: AM12F0422D006

M12 panel receptacle, rear mount, female, contacts:4, PCB dip-solder connection, D code, right angled, IP67View All -

P/N: AM12M0412D001

M12 D Code Male Panel Rear Mount Receptacle For Wires Solder Connector PG9View All -

P/N: AM12F0413D001

M12 panel receptacle, front mount, female, contacts:4, solder connection for wires, D code, straight, IP67View All -

P/N: AM12M0413D351-005

M12 Panel Receptacle Front Mount Male 4Pin Solder Connection For Wires D Code Straight IP67View All -

P/N: AM12F0422D001

M12 panel receptacle, rear mount, female, contacts:4, PCB dip-solder connection, D code, straight, IP67View All -

P/N: AM12M0422D001

M12 panel receptacle, rear mount, male, contacts:4, PCB dip-solder connection, D code, straight, IP67View All -

P/N: AM12F0411D241-010

M12 4P D Code Pre-molded Cable Connector Female Straight IP67View All -

P/N: AM12M0411D241-010

M12 pre-molded cable connector male solder connection D code straight IP67View All

-

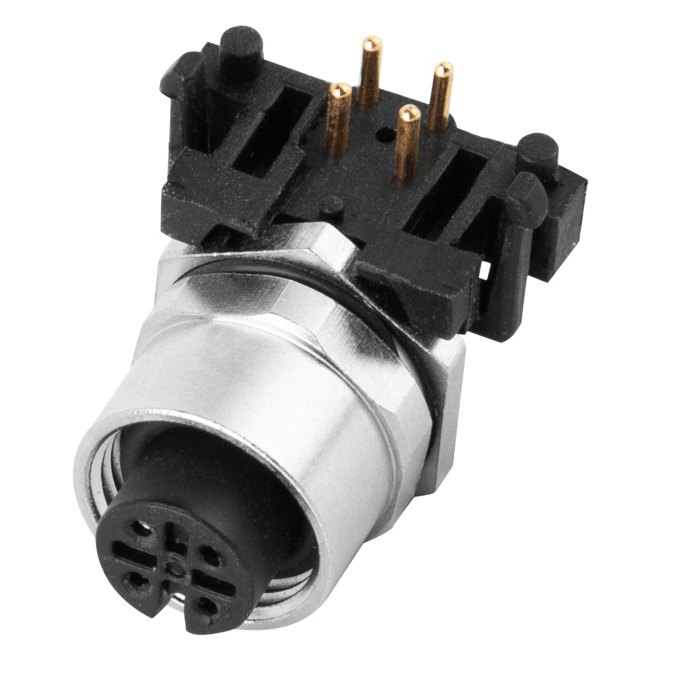

P/N: AM12F0822X008

M12 X Code 8Pole Panel Receptacle Rear Mount Female PCB Dip-solder Connection Right Angled IP67View All -

P/N: AM12M0822X001

M12 Panel Receptacle Rear Mount Male PCB DIP Solder X Code StraightView All -

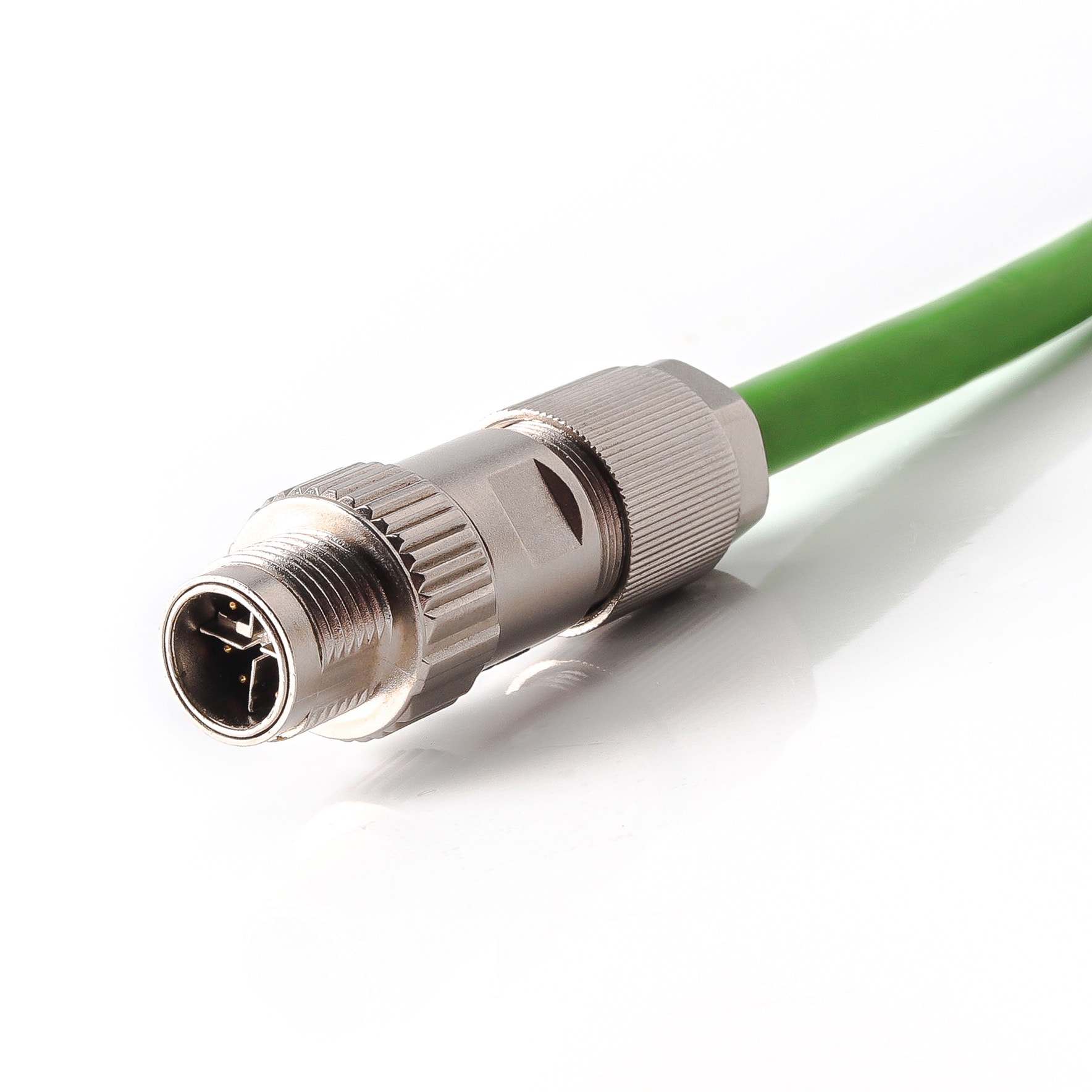

P/N: AM12M0811X003

M12 data cable connector, contact: 8P, male, for pre-molding , X code, straight, 360 EMC shielding, solder connection, 0.5A/60VView All -

P/N: AM12M0844X003

M12 X Code Field Assembly Connector Male EMC Shielded Straight IP67 Crimp ContactsView All -

P/N: AM12M0811X233-100

M12 Pre-molded Cable Connector 8Pole Male X Code EMC Profinet/Ethernet Cable StraightView All -

P/N: AM12F0822X002

M12 X Code Receptacle Panel Rear Mount Female PCB DIP Connection M16*1.5View All -

P/N: AM12F0822X001

M12 X Code Receptacle Panel Rear Mount Female PCB DIP Connection PG9View All -

P/N: AM12F0812X001

M12 X Code Receptacle Panel Rear Mount Female For Solder Wires ConnectionView All

-

P/N: AM12F0822Y002

M12 Hybrid Connector,Y Code,Female,Panel Mount Receptacle,M12 Device ConnectorView All -

P/N: AM12M0822Y002

M12 Hybrid Connector,Y Code,Male,Panel Mount Receptacle,M12 Device ConnectorView All -

P/N: AM12M0811YXX1-XXX

M12 Hybrid Connector,Male,M12 Y-Coded Power Signal Ethernet CableView All -

P/N: AM12F0811YXX1-XXX

M12 Hybrid Connector,Female,Power Signal,M12 Y-Coded CablesView All -

P/N: AM12F0812Y003

M12 Hybrid Connector,Female,Panel Mount Shielded,M12 Y-CodedView All

-

P/N: AM12F0434T001

M12 cable connector, female, contacts: 4, field assembly type, screw connection, T code, straight, IP67View All -

P/N: AM12M0434T001

M12 cable connector, male, contacts: ,4, field assembly type, screw connection, T code, straight, IP67View All -

P/N: AM12F0412T171 -XXX

M12 panel receptacle, female, contacts: 4, solder connection for wires, T code, straight, IP67View All -

P/N: AM12M0412T171-XXX

M12 panel receptacle, male, contacts: 4, solder connection for wires, T code, straight, IP67View All -

P/N: AM12F0322T001

M12 panel receptacle, female, contacts: 3,PCB dip-solder connection, T code, straight, IP67View All -

P/N: AM12M0322T001

M12 panel receptacle, male, contacts: 3,PCB dip-solder connection, T code, straight, IP67View All -

P/N: AM12F0311TXX1-XXX

M12 pre-molded cable connector, female, contacts: 3,solder connection, T code, straight, IP67View All -

P/N: AM12M0311TXX1-XXX

M12 pre-molded cable connector, male, contacts:3, solder connection, T code, straight, IP67View All

-

P/N: AM12F0411SXX1-XXX

M12 pre-molded cable connector, female, contacts:4(3+PE), solder connection, S code, straight, IP67View All -

P/N: AM12M0322S001

M12 panel receptacle, rear mount, male, contacts:3(2+PE),PCB dip-solder connection, S code, straight, IP67View All -

P/N: AM12F0412S171-XXX

M12 panel receptacle, rear mount, female, contacts:4, solder connection for wires, S code, straight, IP67View All -

P/N: AM12M0412S171-XXX

M12 panel receptacle, rear mount, male, contacts:4, solder connection for wires, S code, straight, IP67View All -

P/N: AM12F0322S001

M12 panel receptacle, rear mount, female, contacts:3(2+PE),PCB dip-solder connection, S code, straight, IP67View All -

P/N: AM12M0422S001

M12 panel receptacle, rear mount, male, contacts:,4(3+PE), PCB dip-solder connection, S code, straight, IP67View All -

P/N: AM12F0311SXX1-XXX

M12 pre-molded cable connector, female, contacts:3(2+PE), solder connection, S code, straight, IP67View All -

P/N: AM12F0322S002

M12 panel receptacle, rear mount, female, contacts:3(2+PE), PCB dip-solder connection, S code, straight, IP67View All

-

P/N: AM12M0511Lxx1-xxx

M12 L Coded Power 5P Connector Male Drag Chain Pre-Molded CableView All -

P/N: AM12M0412L171-XXX

M12 panel receptacle, rear mount, male, contacts:4, solder connection for wires, L code, straight, IP67View All -

P/N: AM12M0522L001

M12 panel receptacle, rear mount, male, contacts:5, PCB dip-solder connection, L code, straight, IP67View All -

P/N: AM12F0411LXX2-XXX

M12 pre-molded cable connector, female, contacts:4, solder connection, L code, straight, IP67View All -

P/N: AM12M0411LXX1-XXX

M12 pre-molded cable connector, male, contacts:4, solder connection, L code, straight, IP67View All -

P/N: AM12M0322L001

M12 panel receptacle, rear mount, male, contacts:3, PCB dip-solder connection, L code, straight, IP67View All -

P/N: AM12M0422L001

M12 panel receptacle, rear mount, male, contacts:4,PCB dip-solder connection, L code, straight, IP67View All -

P/N: AM12F0311LXX1-XXX

M12 pre-molded cable connector, female, contacts:3, solder connection, L code, straight, IP67View All

-

P/N: AM12M0312K171-XXX

M12 panel receptacle, rear mount, male, contacts:3,solder connection for wires, K code, straight, IP67View All -

P/N: AM12F0522K001

M12 panel receptacle, rear mount, female, contacts:5, PCB dip-solder connection, K code, straight, IP67View All -

P/N: AM12M0522K001

M12 panel receptacle, rear mount, male, contacts:5,PCB dip-solderconnection, K code, straight, IP67View All -

P/N: AM12F0311KXX1-XXX

M12 pre-molded cable connector, female, contacts:3, solder connection, K code, straight, IP67View All -

P/N: AM12M0311KXX1-XXX

M12 pre-molded cable connector, male, contacts:3, solder connection, K code, straight, IP67View All -

P/N: AM12F0513K371-005

M12 K Code 5P(4+PE) Female Panel Front Mount Receptacle ConnectorView All -

P/N: AM12F0312K171-XXX

M12 panel receptacle, rear mount, female, contacts:3, solder connection for wires, K code, straight, IP67View All

-

P/N: AM12M0512M371-XXX

M12 Device Receptacle M Code Panel Rear Mount Male 5Pin Connector For WiresView All -

P/N: AM12F0322M001

M12 Device Receptacle M Code Panel Rear Mount Female 3Pin PCB ConnectorView All -

P/N: AM12F0612M171-XXX

M12 Device Receptacle M Code Panel Rear Mount Female 6Pin Connector For WiresView All -

P/N: AM12M0612M371-XXX

M12 Device Receptacle M Code Panel Rear Mount Male 6Pin Connector For WiresView All -

P/N: AM12M0522M001

M12 Device Receptacle M Code Panel Rear Mount Male 5Pin PCB ConnectorView All -

P/N: AM12F0611MXX1-XXX

M12 M Code 5+PE Pre-molded Cable 6Pin Female Straight ConnectorView All -

P/N: AM12M0611MXX1-XXX

M12 M Code 5+PE Pre-molded Cable 6Pin Male Straight ConnectorView All -

P/N: AM12F0522M001

M12 Device Receptacle M Code Panel Rear Mount Female 5Pin PCB ConnectorView All

-

P/N: AM09F0522A001

M9 Connector Receptacle Panel Rear Mount Female 5Pole PCB Dip-solderView All -

P/N: AM09F0411A001

M9 pre-molded cable connector, female, contacts:4, solder connection, straight, IP67View All -

P/N: AM09F0311A001

M9 pre-molded cable connector, female, contacts: 3, solder connection, straight, IP67View All -

P/N: AM09F0822A001

M9 Female Panel Rear Mount Receptacle 8Pin PCB Waterproof ConnectorView All -

P/N: AM09F0422A001

M9 4P Female Panel Rear Mount Receptacle PCB Waterproof ConnectorView All -

P/N: AM09F0322A001

M9 3Pole Female Panel Rear Mount Receptacle PCB Waterproof ConnectorView All -

P/N: AM09F0522A201

M9 Female Panel Rear Mount Receptacle 5Pin PCB Connector Right AngledView All

-

P/N: AM16F2422A001

M16 panel receptacle,rear mount,Female, contacts:24, PCB dip- solder connection,straight,IP67,UL certifiedView All -

P/N: AM16M2422A001

M16 panel receptacle,rear mount,male, contacts:24, PCB dip- solder connection,straight,IP67,UL certifiedView All -

P/N: AM16F2411AXX2-XXX

M16 pre-molded cable connector, female, contacts:24, solder connection, right angled, IP67, shieldable, UL certifiedView All -

P/N: AM16M0522B001

M1M16 panel receptacle, rear mount, male, contacts:5, PCB dip-solderconnection, straight, IP67, UL certifiedView All -

P/N: AM16F1222A001

M16 panel receptacle, rear mount, female, contacts:12,PCB connection, straight, IP67, UL certifiedView All -

P/N: AM16M1222A001

M16 panel receptacle, rear mount, male, contacts:12,PCB dip-solder connection, straight, IP67, UL certifiedView All -

P/N: AM16M2411AXX1-XXX

M16 pre-molded cable connector, male, contacts:24, solder connection, straight, IP67, shieldableView All -

P/N: AM16M1214A001

M16 cable connector, male, contacts:12,field assembly type, solder connection, straight, IP67, UL certifiedView All

-

P/N: AM78F0511A162-010

MINI-Change 7/8View All -

P/N: AM78M0522A001

MINI-Change 7/8-16UNF Panel Rear Mount Receptacle Male 5Pin PCB ConnectorView All -

P/N: AM78F0412A371-050

7/8View All -

P/N: AM78M0412A371-050

7/8View All -

P/N: AM78F0512A371-050

7/8View All -

P/N: AM78M0512A371-050

7/8View All -

P/N: AM78F0312A371-050

7/8View All -

P/N: AM78M0312A371-050

7/8View All

-

P/N: AM23M1912A002

M23 Panel Receptacle Rear Mount Male 19P(16+3) Solder Connection For Wires Straight IP67View All -

P/N: AM23F1911AXX1-XXX

M23 Pre-molded Cable Connector Female 19P(16+3) Solder Connection Straight IP67View All -

P/N: AM23M1911AXX1-XXX

M23 Pre-molded Cable Connector Male 19P(16+3) Solder Connection Straight IP67View All

-

P/N: BM24F0212A001

Bayonet Connector BM24 2P Receptacle Panel Mount Solder ConnectView All -

P/N: BM24M0214A001

Bayonet Connector BM24 2P Plug Connector Field InstallationView All -

P/N: BM24M0314A001

Bayonet Connector BM24 3P Plug Connector Field InstallationView All -

P/N: BM24F0312A001

Bayonet Connector BM24 3P Receptacle Panel Mount Solder ConnectView All -

P/N: BM24M0414A001

Bayonet Connector BM24 4P Plug Connector Field InstallationView All -

P/N: BM24F0412A001

Bayonet Connector BM24 4P Receptacle Panel Mount Solder ConnectView All -

P/N: BM24M1214A001

Bayonet Connector BM24 12P Plug Connector Field InstallationView All -

P/N: BM24F1222A001

Bayonet Connector BM24 12P Receptacle Panel Mount PCB ConnectView All

Industrial Cable Harnesses

-

P/N: AM12F0411D241-010

M12 4P D Code Pre-molded Cable Connector Female Straight IP67View All -

P/N: AM12M0411D241-010

M12 pre-molded cable connector male solder connection D code straight IP67View All -

P/N: AM12F0812X003

M12 Device Connector X Code Female EMC Shielded Panel Rear Mount ReceptacleView All -

P/N: AM12M0811X231-030

M12 Pre-molded Cable Connector 8Pole Male X Code Cable StraightView All -

P/N: AM12F0411BXX1-XXX

M12 pre-molded cable connector, female, contacts:4, solder connection, B code, straight, IP67View All -

P/N: AM12F0511A241-010

M12 FieldBUS Cable Industrial Automation DeviceNet CanOpen CableView All -

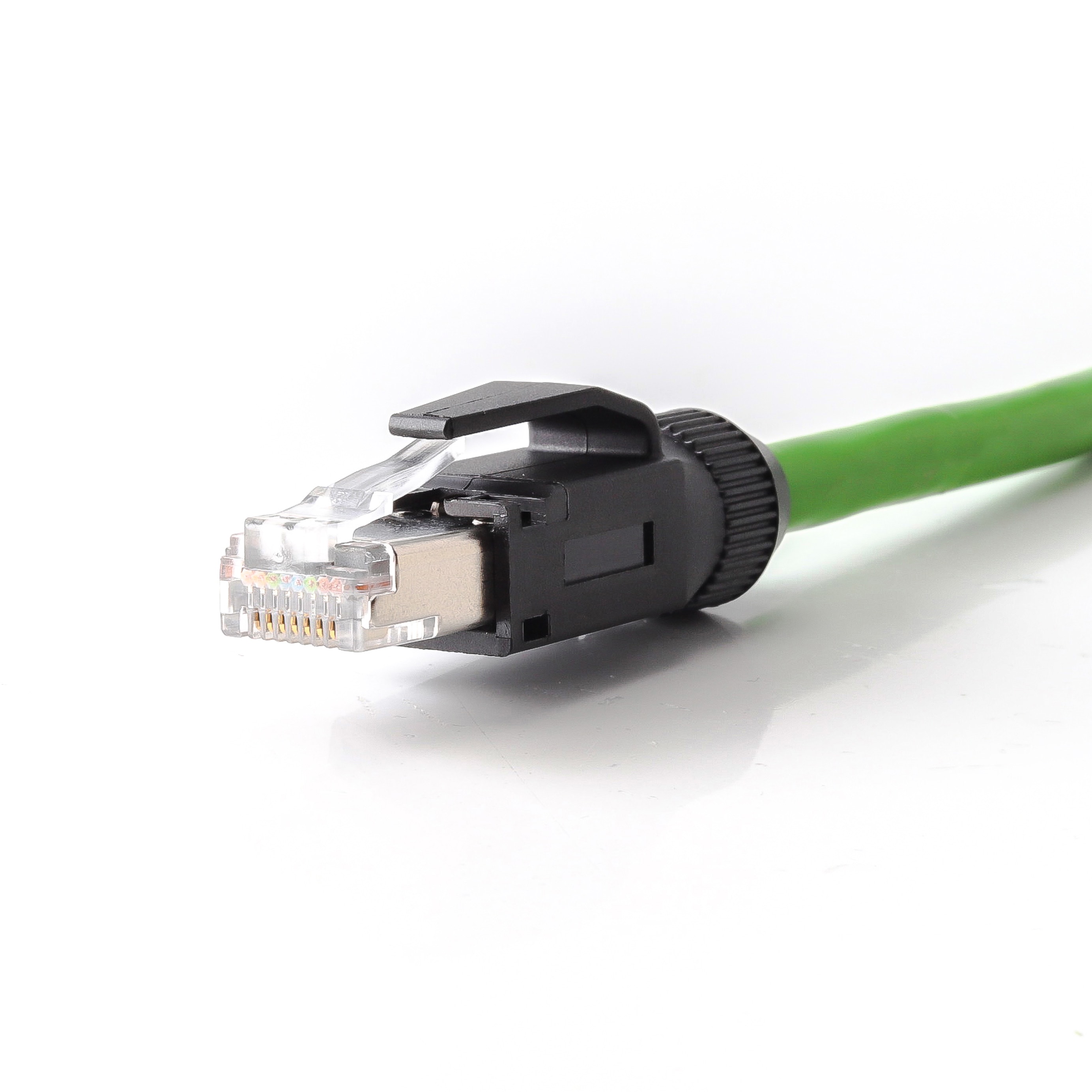

P/N: EhterNet Cable

EhterNet Cable CAT5/CAT6/CAT7 PROFIBUS Industrial Network cableView All -

P/N: AM12M0814X221-010

M12 X Code Male ProfiNET/EtherNET Cable M12 Connector X CodedView All

-

P/N: AM12F0411D241-010

M12 4P D Code Pre-molded Cable Connector Female Straight IP67View All -

P/N: AM78M0411A272-050

DeviceNET 7/8View All -

P/N: AM12F0411BXX1-XXX

M12 pre-molded cable connector, female, contacts:4, solder connection, B code, straight, IP67View All -

P/N: AM12F0511A241-010

M12 FieldBUS Cable Industrial Automation DeviceNet CanOpen CableView All -

P/N: AM78M0511A172-030

MINI-Change 7/8View All

-

P/N: AM12M0411D241-010

M12 pre-molded cable connector male solder connection D code straight IP67View All -

P/N: AM12F0812X003

M12 Device Connector X Code Female EMC Shielded Panel Rear Mount ReceptacleView All -

P/N: AM12M0811X231-030

M12 Pre-molded Cable Connector 8Pole Male X Code Cable StraightView All -

P/N: EhterNet Cable

EhterNet Cable CAT5/CAT6/CAT7 PROFIBUS Industrial Network cableView All -

P/N: AM12M0811YXX1-XXX

M12 Hybrid Connector,Male,M12 Y-Coded Power Signal Ethernet CableView All -

P/N: AM12F0811YXX1-XXX

M12 Hybrid Connector,Female,Power Signal,M12 Y-Coded CablesView All -

P/N: AM12F0812Y003

M12 Hybrid Connector,Female,Panel Mount Shielded,M12 Y-CodedView All

-

P/N: AM78H0511A433-XXX

Electrical Automation Power Supply Connector Cable 7/8-16UNF Pre-molded H-SplitterView All -

P/N: AM12H0811AXX1-XXX

M12 A Code 8P/4P Connector Y-Splitter Industrial Automation Sensor CableView All -

P/N: AM08Y0411A001-000

M8 Y-Splitter Electrical Automation Sensor Connector AdapterView All

Underwater Connectors and Cables

-

P/N: RMK5F

RMK5F 2, 3, 4, 5, 6 And 8 Contacts Deepsea Watertight ConnectorsView All -

P/N: MCDLS-F

MCDLS-F 2, 3, 4, 5, 6 and 8 contacts Deepsea Watertight ConnectorsView All -

P/N: MCBH5MTI

MCBH5MTI 2, 3, 4, 5, 6 And 8 Contacts Deepsea Watertight ConnectorsView All -

P/N: HPBH9M

HPBH9M 9 Contacts Deepsea Watertight ConnectorsView All -

P/N: HF75 50CXBH6F

HF75 50CXBH6F 6 Contacts Deepsea Watertight ConnectorsView All -

P/N: DMCIL13F M

DMCIL13F M 13 contacts Underwater cable connectorView All -

P/N: AWQ7-42

AWQ7-42 24, 28, 32, 36, 42 contacts Underwater cable connectorView All -

P/N: 1L25F M

1L25F M Circular 12, 16, 25 Contacts Underwater ConnectorView All

company

News

-

Amissiontech to Showcase Smart Interconnection Solutions at SPS 2025 in NurembergView All

Amissiontech to Showcase Smart Interconnection Solutions at SPS 2025 in NurembergView All -

2025 Tokyo International Manufacturing Expo: A Perfect ConclusionView All

2025 Tokyo International Manufacturing Expo: A Perfect ConclusionView All -

Amissiontech to Showcase Advanced Industrial Connectors and I/O Solutions at Manufacturing World Japan 2025View All

Amissiontech to Showcase Advanced Industrial Connectors and I/O Solutions at Manufacturing World Japan 2025View All -

Amissiontech Reflects on a Successful Participation at ProPak China 2025View All

Amissiontech Reflects on a Successful Participation at ProPak China 2025View All -

Amissiontech Team-Building Activity at Hailing IslandView All

Amissiontech Team-Building Activity at Hailing IslandView All -

Dragon Boat Festival Greetings: Celebrating Tradition with AmissiontechView All

Dragon Boat Festival Greetings: Celebrating Tradition with AmissiontechView All -

Celebrating Women at Amissiontech on International Women’s DayView All

Celebrating Women at Amissiontech on International Women’s DayView All -

Amissiontech Invites You to HANNOVER MESSE 2025View All

Amissiontech Invites You to HANNOVER MESSE 2025View All

-

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All -

What is an M12 A coded connector?View All

What is an M12 A coded connector?View All -

What Do You Know M12 B Coded?View All

What Do You Know M12 B Coded?View All -

Revolutionizing Field I/O Signal Transmission with Amissiontech's IO-Link HUBView All

Revolutionizing Field I/O Signal Transmission with Amissiontech's IO-Link HUBView All -

Exploring the Technology Behind Underwater Connectors and CablesView All

Exploring the Technology Behind Underwater Connectors and CablesView All -

Amissiontech's IO-LINK Modules Shine at HANNOVER MESSE 2024View All

Amissiontech's IO-LINK Modules Shine at HANNOVER MESSE 2024View All -

Circular ConnectorView All

Circular ConnectorView All -

IO-Link Module - Connects Future Digital CommunicationsView All

IO-Link Module - Connects Future Digital CommunicationsView All

-

Understanding Ethernet MHz Speed and Its Impact on Network PerformanceView All

Understanding Ethernet MHz Speed and Its Impact on Network PerformanceView All -

Top 10 Cable Types and Their UsesView All

Top 10 Cable Types and Their UsesView All -

HDMI vs VGA: Understanding the Key Differences for Industrial & Custom Cable ApplicationsView All

HDMI vs VGA: Understanding the Key Differences for Industrial & Custom Cable ApplicationsView All -

Complete Guide to Ethernet Cable CategoriesView All

Complete Guide to Ethernet Cable CategoriesView All -

Wire Harness Production ExplainedView All

Wire Harness Production ExplainedView All -

Industrial HDMI Shielded Cable Technology InterpretationView All

Industrial HDMI Shielded Cable Technology InterpretationView All -

Revolutionize Automation with DeviceNet-Compatible ToolsView All

Revolutionize Automation with DeviceNet-Compatible ToolsView All -

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All

Industries and Solutions

Solutions

Industries

News And Events

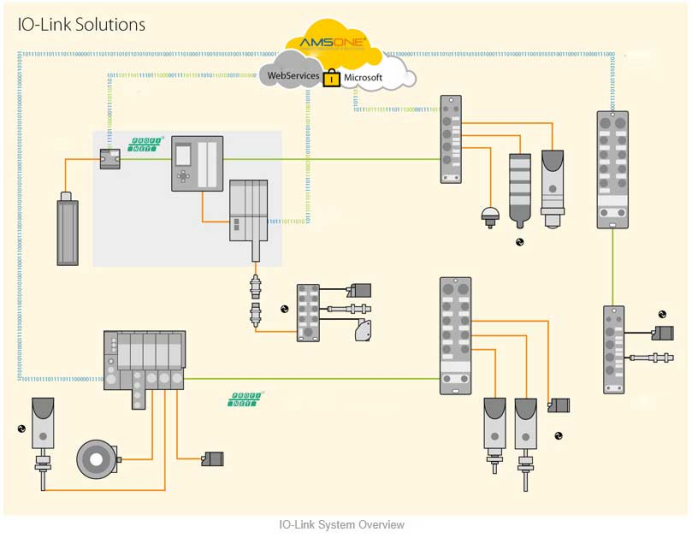

Unlocking the Power of IO-Link Technology: Amissiontech's Advancements

In the fast-paced world of industrial automation, sensors and actuators have evolved significantly, boasting integrated microprocessors that enable tasks like parameterization, configuration data storage, and indication control. Nevertheless, there's an ever-growing need to break free from the confines of traditional binary standard interfaces and provide a centralized means to access additional functions within the automation system. Recognizing this challenge, esteemed manufacturers in the automation industry have united to craft a communication interface tailored specifically for sensors and actuators, one that operates independently of fieldbus protocols. This innovative interface, known as IO-Link, promises to elevate the capabilities and accessibility of these devices within the broader automation ecosystem.

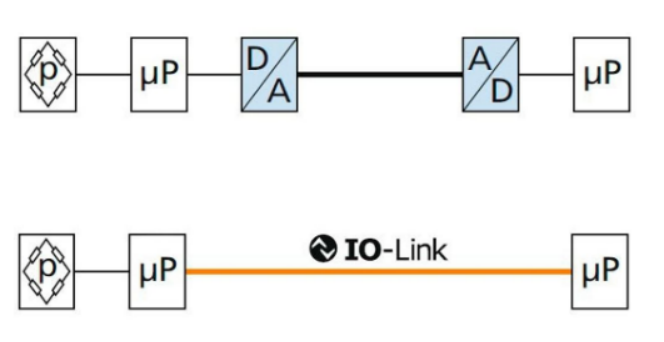

The Technology Behind IO-Link

IO-Link operates on a point-to-point connection model, directly linking sensors or actuators to an interface module. Historically, this binary connection was primarily utilized for transmitting basic switching information. However, IO-Link has taken a giant leap forward by introducing a combined switching status and data channel capable of transferring two bytes of data within a 2 ms cycle. This expanded functionality now facilitates the exchange of various types of information beyond just process values. Parameters and diagnostic messages, for example, can be seamlessly communicated, making universal communication with sensors and actuators a reality, extending its reach down to the very last meter of the automation system.

Integration into Profinet Systems

Until recently, the integration of IO-Link devices into Profinet projects presented challenges for users. Manually inputting device properties such as device class or manufacturer ID and configuring parameters like measuring ranges and output signals often required additional programming or separate software tools. Amissiontech has pioneered a solution to streamline this process with a new feature called Simple IO-Link Device Integration (SIDI). SIDI enables the seamless integration of IO-Link devices directly into Profinet engineering software, such as the TIA Portal. In this approach, IO-Link devices are treated as Profinet submodules within the Generic Station Description Markup Language (GSDML) of the IO-Link masters. Amissiontech has made this integration even more accessible by including all of its proprietary IO-Link devices, as well as devices from its strategic partner for optical sensors.

When the connected device is listed in the SIDI GSDML, PLC programmers enjoy the convenience of selecting it directly from the device catalog within their programming environment. This selection grants them access to a comprehensive overview of all pertinent IO-Link properties associated with these devices. Moreover, they have the ability to modify parameters like measuring ranges, output signals, or pulse rates using a straightforward plain text field. This streamlined process facilitates offline engineering with IO-Link devices, allowing for efficient configuration even when not connected to the physical equipment.

Advantages of IO-Link from Amissiontech

1. Precision Redefined:

Traditional sensors often undergo multiple conversions into both digital and analog data before reaching the final evaluation within the PLC, potentially leading to a loss of precision in measured values. In contrast, IO-Link transmits data exclusively in a purely digital format using a 24 V signal, preserving the exactness of the measured values without any conversions. Furthermore, signal transmission remains highly resilient to external influences, eliminating the need for shielded cables and associated grounding, as data can now be transmitted through industry-standard cables. Additionally, the adoption of this new technology renders costly analog input cards obsolete. Amissiontech's hygienic pressure sensors, for instance, now offer continuous level detection in pressure tanks, resolving inaccuracies introduced by conversion losses and electromagnetic interference during analog signal transmission.

2. Independence Amplified:

IO-Link masters pave the way for the seamless integration of IO-Link devices within a wide spectrum of fieldbus and control system infrastructures, extending compatibility to interfaces like PROFINET, EtherNet/IP, or AS-i, among others. The programming process is streamlined through the incorporation of function blocks within the PLC. IO-Link, conceived as an open standard, has continually evolved through collaborative efforts by prominent manufacturers in the automation industry. Additionally, it enables the connection of actuators such as valve terminals to IO-Link masters, resulting in a significantly more adaptable and streamlined plant infrastructure.

3. Integration Simplified:

In applications such as cooling circuits, monitoring multiple process variables is commonplace to ensure precise process control. Typically, traditional measuring points involve multiple sensors, each tasked with detecting specific parameters like flow rate, total quantity, and temperature. IO-Link sensors, however, are capable of measuring and digitally transmitting multiple process values within a single unit. For instance, an IO-Link flow sensor can accurately capture all three of these values and transmit them digitally using a standard 3-wire cable. This streamlined approach substantially reduces costs related to configuration, installation, and the inventory of spare sensors.

4. Remote Configuration and Enhanced Security:

IO-Link device parameters can be conveniently modified using dedicated parameter setting software like moneo configure. This capability facilitates swift adjustments and minimizes downtime in industrial processes. IO-Link sensors offer the option to be locked either using the sensor's operating keys or remotely through the software. This locking feature ensures that parameter changes cannot be altered without access to the software, preventing inadvertent or deliberate adjustments to the sensor's settings. Additionally, the moneo configure software enables users to save device configurations and generate detailed setting protocols for documentation and reference purposes.

5. Advanced Monitoring and Diagnostics:

IO-Link enables the concurrent transmission of both process and service data, including the retrieval of diagnostic information such as minimum and maximum values, or the detection of issues like wire breaks or short circuits. These acyclically accessible diagnostic data provide the foundation for condition-based maintenance practices, ultimately leading to increased operational uptime. Crucially, this diagnostic data remains accessible even during system operation. In a cooling circuit, for example, precise monitoring of flow rates is accomplished using magnetic-inductive inline volumetric flow sensors from the SM series. In the event of an error, the master device communicates the diagnostic data to the controller, allowing for the unequivocal identification of the malfunctioning sensor. This streamlined process enhances system reliability and simplifies maintenance procedures.

Amissiontech and IO-Link: Transforming Automation Today

IO-Link technology represents a major leap forward in industrial automation, and Amissiontech is a pioneer in harnessing its potential. From accuracy and independence to simplified integration, remote configuration and advanced monitoring, IO-Link offers numerous benefits that are reshaping industrial processes. Amissiontech invites you to embrace the future of automation, where efficiency, accuracy and innovation come together to create a smarter world of industrial automation.

Related article: Amissiontech's Mastery of IO-Link and Collaborative Technological Advancements