Products

I/O Systems

-

IO Link Hub NPN 0.5A/channel Plastic Housing Plastic Thread LockingView All

IO Link Hub NPN 0.5A/channel Plastic Housing Plastic Thread LockingView All -

P/N: ALD-HBN1-354XXX

IO Link Hub NPN 0.5A/channel Metal Housing Metal Thread / Bayonet LockingView All -

P/N: ALD-HBN1-310XXX

IO Link Hub NPN 0.5A/channel Metal Housing Metal Thread LockingView All -

P/N: ALD-HBP1-372XXX

IO Link Hub PNP 2A/channel Plastic Housing Plastic Thread LockingView All -

P/N: ALD-HBP2-364XXX

IO Link Hub PNP 2A/channel Plastic Housing Metal Thread/Bayonet LockingView All -

P/N: ALD-HBP1-372XXX

IO Link Hub PNP 0.5A/channel Plastic Housing Plastic Thread LockingView All -

P/N: ALD-HBP1-351XXX

IO Link Hub PNP 0.5A/channel Plastic Housing Metal Thread/Bayonet LockingView All -

P/N: ALD-HBP2-330XXX

IO Link Hub PNP 2A/channel Metal Housing Metal Thread LockingView All

-

P/N: ALM-MPA1-051XXX

IO Link Master Multiprotocol Plastic Housing 7/8 Power ConnectorView All -

P/N: ALM-ECA1-010XXX

IO Link Master EtherCAT Single ProtocolView All -

P/N: ALM-MPA1-041XXX

IO Link Master Multiprotocol Plastic Housing M12 L-Codedd Power ConnectorView All -

P/N: ALM-MPA1-030XXX

IO Link Master Multiprotocol Metal Housing M12 L-Codedd Power ConnectorView All -

P/N: ALM-PNA1-010XXX

IO Link Master Profitnet Single ProtocolView All

Circular Connectors

-

P/N: AM08M0411AXX1-XXX

M8 4Pin Pre-molded Cable Male Straight M8 ConnectorView All -

P/N: AM08F0822A001

M8 Device Connector Panel Rear Mount M8 8P Female ReceptacleView All -

P/N: AM08M0622A001

M8 Device Connector Panel Rear Mount M8 6P Male ReceptacleView All -

P/N: AM08M0811AXX1-XXX

M8 8Pin Pre-molded Cable Male Straight M8 ConnectorView All -

P/N: AM08M0822A003

M8 Device Connector Male 8Pin PCB Receptacle Panel Rear Mount Right Angled ShieldedView All -

P/N: AM08M0822A001

M8 Device Connector Panel Rear Mount M8 8P Male ReceptacleView All -

P/N: AM08F0811AXX3-XXX

M8 8P Female Shield Connector Pre-molded Cable Right Angled IP67View All -

P/N: AM08M0811AXX3-XXX

M8 Connector 8P Male Shield Pre-molded Cable Right Angled IP67View All

-

P/N: AM12F1211AXX1-XXX

M12 pre-molded cable connector, female, contacts: 12,solder connection, A code, straight, IP67View All -

P/N: AM12F0822A005

M12 panel receptacle, rear mount, female, contacts: 8, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12F0522A005

M12 panel receptacle, rear mount, female, contacts: 5, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12F0512AXX1-XXX

M12 panel receptacle, rear mount, female, contacts: 5, solder connection for wires, A code, straight, IP67View All -

P/N: AM12M0422A005

M12 panel receptacle, rear mount, male, contacts: 4, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12M0522A005

M12 panel receptacle, rear mount, male, contacts: 5, PCB dip-solder connection, A code, right angled, IP67View All -

P/N: AM12F0534A007

M12 cable connector, female, contacts:5, field assembly type, screw connection, A code, right angled, IP67View All -

P/N: AM12M0822A005

M12 panel receptacle, rear mount, male, contacts: 8, PCB dip-solder connection, A code, right angled, IP67View All

-

P/N: AM12F0522B001

M12 panel receptacle, rear mount, female, contacts:5, solder connection, B code, straight, IP67View All -

P/N: AM12M0522B001

M12 B Code Male Panel Rear Mount Receptacle PCB Connector PG9View All -

P/N: AM12F0511BXX1-XXX

M12 pre-molded cable connector, female, contacts:5, solder connection, B code, straight, IP67View All -

P/N: AM12M0511BXX1-XXX

M12 pre-molded cable connector, male, contacts:5, solder connection, B code, straight, IP67View All -

P/N: AM12F0422B001

M12 panel receptacle, rear mount, female, contacts:4, PCB dip-solder connection, B code, straight, IP67View All -

P/N: AM12M0422B001

M12 panel receptacle, rear mount, male, contacts:4, PCB dip-solder connection, B code, straight, IP67View All -

P/N: AM12M0512B002

M12 5P Male B Code Panel Rear Mount Receptacle Wires Solder Connector M16*1.5View All -

P/N: AM12M0512B001

M12 5P Male B Code Panel Rear Mount Receptacle Wires Solder Connector PG9View All

-

P/N: AM12F0422D006

M12 panel receptacle, rear mount, female, contacts:4, PCB dip-solder connection, D code, right angled, IP67View All -

P/N: AM12M0412D001

M12 D Code Male Panel Rear Mount Receptacle For Wires Solder Connector PG9View All -

P/N: AM12F0413D001

M12 panel receptacle, front mount, female, contacts:4, solder connection for wires, D code, straight, IP67View All -

P/N: AM12M0413D351-005

M12 Panel Receptacle Front Mount Male 4Pin Solder Connection For Wires D Code Straight IP67View All -

P/N: AM12F0422D001

M12 panel receptacle, rear mount, female, contacts:4, PCB dip-solder connection, D code, straight, IP67View All -

P/N: AM12M0422D001

M12 panel receptacle, rear mount, male, contacts:4, PCB dip-solder connection, D code, straight, IP67View All -

P/N: AM12F0411D241-010

M12 4P D Code Pre-molded Cable Connector Female Straight IP67View All -

P/N: AM12M0411D241-010

M12 pre-molded cable connector male solder connection D code straight IP67View All

-

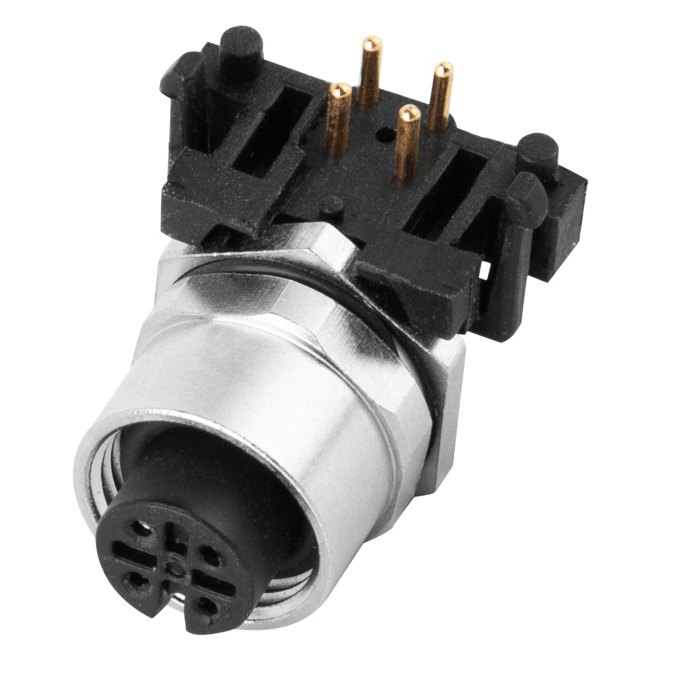

P/N: AM12F0822X008

M12 X Code 8Pole Panel Receptacle Rear Mount Female PCB Dip-solder Connection Right Angled IP67View All -

P/N: AM12M0822X001

M12 Panel Receptacle Rear Mount Male PCB DIP Solder X Code StraightView All -

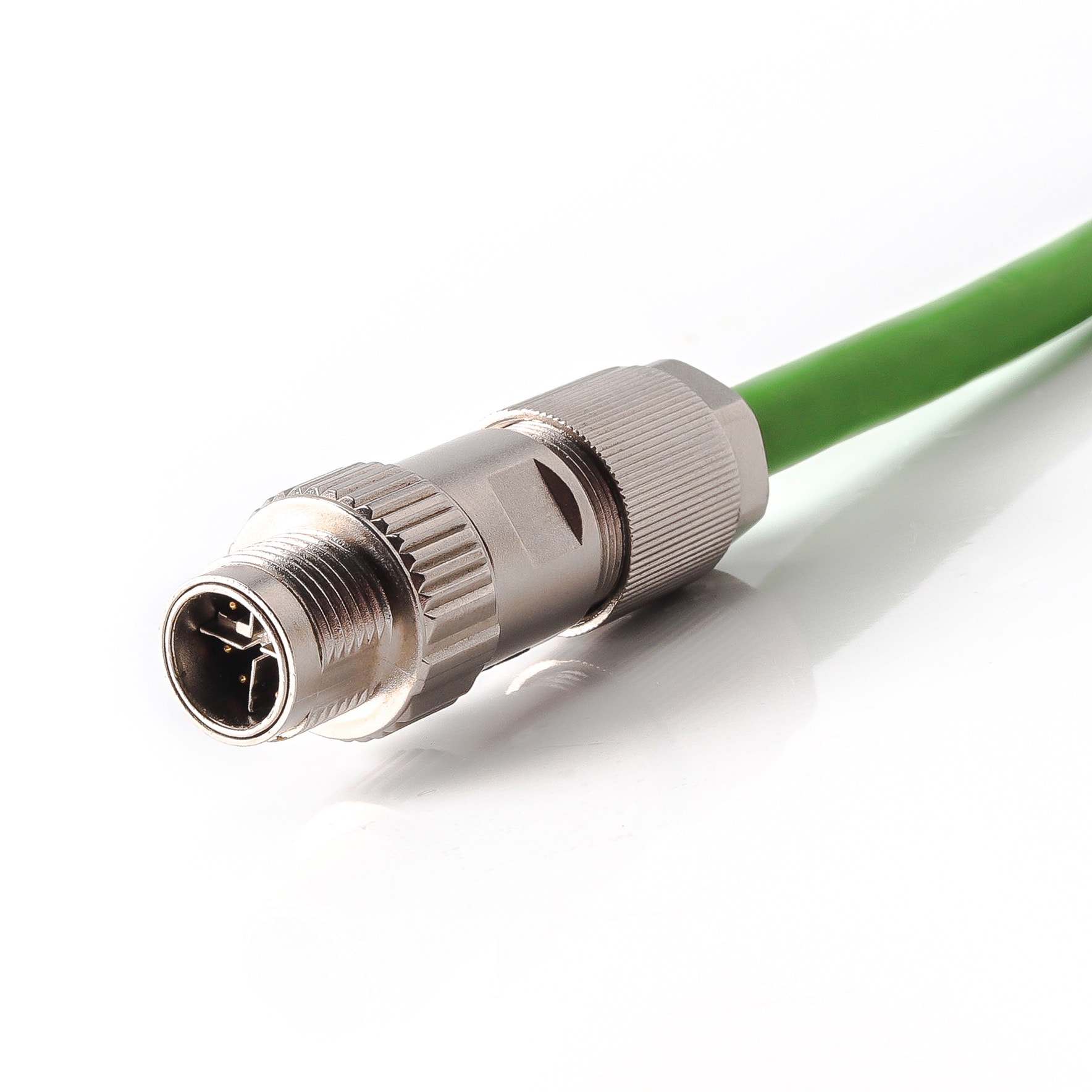

P/N: AM12M0811X003

M12 data cable connector, contact: 8P, male, for pre-molding , X code, straight, 360 EMC shielding, solder connection, 0.5A/60VView All -

P/N: AM12M0844X003

M12 X Code Field Assembly Connector Male EMC Shielded Straight IP67 Crimp ContactsView All -

P/N: AM12M0811X233-100

M12 Pre-molded Cable Connector 8Pole Male X Code EMC Profinet/Ethernet Cable StraightView All -

P/N: AM12F0822X002

M12 X Code Receptacle Panel Rear Mount Female PCB DIP Connection M16*1.5View All -

P/N: AM12F0822X001

M12 X Code Receptacle Panel Rear Mount Female PCB DIP Connection PG9View All -

P/N: AM12F0812X001

M12 X Code Receptacle Panel Rear Mount Female For Solder Wires ConnectionView All

-

P/N: AM12F0822Y002

M12 Hybrid Connector,Y Code,Female,Panel Mount Receptacle,M12 Device ConnectorView All -

P/N: AM12M0822Y002

M12 Hybrid Connector,Y Code,Male,Panel Mount Receptacle,M12 Device ConnectorView All -

P/N: AM12M0811YXX1-XXX

M12 Hybrid Connector,Male,M12 Y-Coded Power Signal Ethernet CableView All -

P/N: AM12F0811YXX1-XXX

M12 Hybrid Connector,Female,Power Signal,M12 Y-Coded CablesView All -

P/N: AM12F0812Y003

M12 Hybrid Connector,Female,Panel Mount Shielded,M12 Y-CodedView All

-

P/N: AM12F0434T001

M12 cable connector, female, contacts: 4, field assembly type, screw connection, T code, straight, IP67View All -

P/N: AM12M0434T001

M12 cable connector, male, contacts: ,4, field assembly type, screw connection, T code, straight, IP67View All -

P/N: AM12F0412T171 -XXX

M12 panel receptacle, female, contacts: 4, solder connection for wires, T code, straight, IP67View All -

P/N: AM12M0412T171-XXX

M12 panel receptacle, male, contacts: 4, solder connection for wires, T code, straight, IP67View All -

P/N: AM12F0322T001

M12 panel receptacle, female, contacts: 3,PCB dip-solder connection, T code, straight, IP67View All -

P/N: AM12M0322T001

M12 panel receptacle, male, contacts: 3,PCB dip-solder connection, T code, straight, IP67View All -

P/N: AM12F0311TXX1-XXX

M12 pre-molded cable connector, female, contacts: 3,solder connection, T code, straight, IP67View All -

P/N: AM12M0311TXX1-XXX

M12 pre-molded cable connector, male, contacts:3, solder connection, T code, straight, IP67View All

-

P/N: AM12F0411SXX1-XXX

M12 pre-molded cable connector, female, contacts:4(3+PE), solder connection, S code, straight, IP67View All -

P/N: AM12M0322S001

M12 panel receptacle, rear mount, male, contacts:3(2+PE),PCB dip-solder connection, S code, straight, IP67View All -

P/N: AM12F0412S171-XXX

M12 panel receptacle, rear mount, female, contacts:4, solder connection for wires, S code, straight, IP67View All -

P/N: AM12M0412S171-XXX

M12 panel receptacle, rear mount, male, contacts:4, solder connection for wires, S code, straight, IP67View All -

P/N: AM12F0322S001

M12 panel receptacle, rear mount, female, contacts:3(2+PE),PCB dip-solder connection, S code, straight, IP67View All -

P/N: AM12M0422S001

M12 panel receptacle, rear mount, male, contacts:,4(3+PE), PCB dip-solder connection, S code, straight, IP67View All -

P/N: AM12F0311SXX1-XXX

M12 pre-molded cable connector, female, contacts:3(2+PE), solder connection, S code, straight, IP67View All -

P/N: AM12F0322S002

M12 panel receptacle, rear mount, female, contacts:3(2+PE), PCB dip-solder connection, S code, straight, IP67View All

-

P/N: AM12M0511Lxx1-xxx

M12 L Coded Power 5P Connector Male Drag Chain Pre-Molded CableView All -

P/N: AM12M0412L171-XXX

M12 panel receptacle, rear mount, male, contacts:4, solder connection for wires, L code, straight, IP67View All -

P/N: AM12M0522L001

M12 panel receptacle, rear mount, male, contacts:5, PCB dip-solder connection, L code, straight, IP67View All -

P/N: AM12F0411LXX2-XXX

M12 pre-molded cable connector, female, contacts:4, solder connection, L code, straight, IP67View All -

P/N: AM12M0411LXX1-XXX

M12 pre-molded cable connector, male, contacts:4, solder connection, L code, straight, IP67View All -

P/N: AM12M0322L001

M12 panel receptacle, rear mount, male, contacts:3, PCB dip-solder connection, L code, straight, IP67View All -

P/N: AM12M0422L001

M12 panel receptacle, rear mount, male, contacts:4,PCB dip-solder connection, L code, straight, IP67View All -

P/N: AM12F0311LXX1-XXX

M12 pre-molded cable connector, female, contacts:3, solder connection, L code, straight, IP67View All

-

P/N: AM12M0312K171-XXX

M12 panel receptacle, rear mount, male, contacts:3,solder connection for wires, K code, straight, IP67View All -

P/N: AM12F0522K001

M12 panel receptacle, rear mount, female, contacts:5, PCB dip-solder connection, K code, straight, IP67View All -

P/N: AM12M0522K001

M12 panel receptacle, rear mount, male, contacts:5,PCB dip-solderconnection, K code, straight, IP67View All -

P/N: AM12F0311KXX1-XXX

M12 pre-molded cable connector, female, contacts:3, solder connection, K code, straight, IP67View All -

P/N: AM12M0311KXX1-XXX

M12 pre-molded cable connector, male, contacts:3, solder connection, K code, straight, IP67View All -

P/N: AM12F0513K371-005

M12 K Code 5P(4+PE) Female Panel Front Mount Receptacle ConnectorView All -

P/N: AM12F0312K171-XXX

M12 panel receptacle, rear mount, female, contacts:3, solder connection for wires, K code, straight, IP67View All

-

P/N: AM12M0512M371-XXX

M12 Device Receptacle M Code Panel Rear Mount Male 5Pin Connector For WiresView All -

P/N: AM12F0322M001

M12 Device Receptacle M Code Panel Rear Mount Female 3Pin PCB ConnectorView All -

P/N: AM12F0612M171-XXX

M12 Device Receptacle M Code Panel Rear Mount Female 6Pin Connector For WiresView All -

P/N: AM12M0612M371-XXX

M12 Device Receptacle M Code Panel Rear Mount Male 6Pin Connector For WiresView All -

P/N: AM12M0522M001

M12 Device Receptacle M Code Panel Rear Mount Male 5Pin PCB ConnectorView All -

P/N: AM12F0611MXX1-XXX

M12 M Code 5+PE Pre-molded Cable 6Pin Female Straight ConnectorView All -

P/N: AM12M0611MXX1-XXX

M12 M Code 5+PE Pre-molded Cable 6Pin Male Straight ConnectorView All -

P/N: AM12F0522M001

M12 Device Receptacle M Code Panel Rear Mount Female 5Pin PCB ConnectorView All

-

P/N: AM09F0522A001

M9 Connector Receptacle Panel Rear Mount Female 5Pole PCB Dip-solderView All -

P/N: AM09F0411A001

M9 pre-molded cable connector, female, contacts:4, solder connection, straight, IP67View All -

P/N: AM09F0311A001

M9 pre-molded cable connector, female, contacts: 3, solder connection, straight, IP67View All -

P/N: AM09F0822A001

M9 Female Panel Rear Mount Receptacle 8Pin PCB Waterproof ConnectorView All -

P/N: AM09F0422A001

M9 4P Female Panel Rear Mount Receptacle PCB Waterproof ConnectorView All -

P/N: AM09F0322A001

M9 3Pole Female Panel Rear Mount Receptacle PCB Waterproof ConnectorView All -

P/N: AM09F0522A201

M9 Female Panel Rear Mount Receptacle 5Pin PCB Connector Right AngledView All

-

P/N: AM16F2422A001

M16 panel receptacle,rear mount,Female, contacts:24, PCB dip- solder connection,straight,IP67,UL certifiedView All -

P/N: AM16M2422A001

M16 panel receptacle,rear mount,male, contacts:24, PCB dip- solder connection,straight,IP67,UL certifiedView All -

P/N: AM16F2411AXX2-XXX

M16 pre-molded cable connector, female, contacts:24, solder connection, right angled, IP67, shieldable, UL certifiedView All -

P/N: AM16M0522B001

M1M16 panel receptacle, rear mount, male, contacts:5, PCB dip-solderconnection, straight, IP67, UL certifiedView All -

P/N: AM16F1222A001

M16 panel receptacle, rear mount, female, contacts:12,PCB connection, straight, IP67, UL certifiedView All -

P/N: AM16M1222A001

M16 panel receptacle, rear mount, male, contacts:12,PCB dip-solder connection, straight, IP67, UL certifiedView All -

P/N: AM16M2411AXX1-XXX

M16 pre-molded cable connector, male, contacts:24, solder connection, straight, IP67, shieldableView All -

P/N: AM16M1214A001

M16 cable connector, male, contacts:12,field assembly type, solder connection, straight, IP67, UL certifiedView All

-

P/N: AM78F0511A162-010

MINI-Change 7/8View All -

P/N: AM78M0522A001

MINI-Change 7/8-16UNF Panel Rear Mount Receptacle Male 5Pin PCB ConnectorView All -

P/N: AM78F0412A371-050

7/8View All -

P/N: AM78M0412A371-050

7/8View All -

P/N: AM78F0512A371-050

7/8View All -

P/N: AM78M0512A371-050

7/8View All -

P/N: AM78F0312A371-050

7/8View All -

P/N: AM78M0312A371-050

7/8View All

-

P/N: AM23M1912A002

M23 Panel Receptacle Rear Mount Male 19P(16+3) Solder Connection For Wires Straight IP67View All -

P/N: AM23F1911AXX1-XXX

M23 Pre-molded Cable Connector Female 19P(16+3) Solder Connection Straight IP67View All -

P/N: AM23M1911AXX1-XXX

M23 Pre-molded Cable Connector Male 19P(16+3) Solder Connection Straight IP67View All

-

P/N: BM24F0212A001

Bayonet Connector BM24 2P Receptacle Panel Mount Solder ConnectView All -

P/N: BM24M0214A001

Bayonet Connector BM24 2P Plug Connector Field InstallationView All -

P/N: BM24M0314A001

Bayonet Connector BM24 3P Plug Connector Field InstallationView All -

P/N: BM24F0312A001

Bayonet Connector BM24 3P Receptacle Panel Mount Solder ConnectView All -

P/N: BM24M0414A001

Bayonet Connector BM24 4P Plug Connector Field InstallationView All -

P/N: BM24F0412A001

Bayonet Connector BM24 4P Receptacle Panel Mount Solder ConnectView All -

P/N: BM24M1214A001

Bayonet Connector BM24 12P Plug Connector Field InstallationView All -

P/N: BM24F1222A001

Bayonet Connector BM24 12P Receptacle Panel Mount PCB ConnectView All

Industrial Cable Harnesses

-

P/N: AM12F0411D241-010

M12 4P D Code Pre-molded Cable Connector Female Straight IP67View All -

P/N: AM12M0411D241-010

M12 pre-molded cable connector male solder connection D code straight IP67View All -

P/N: AM12F0812X003

M12 Device Connector X Code Female EMC Shielded Panel Rear Mount ReceptacleView All -

P/N: AM12M0811X231-030

M12 Pre-molded Cable Connector 8Pole Male X Code Cable StraightView All -

P/N: AM12F0411BXX1-XXX

M12 pre-molded cable connector, female, contacts:4, solder connection, B code, straight, IP67View All -

P/N: AM12F0511A241-010

M12 FieldBUS Cable Industrial Automation DeviceNet CanOpen CableView All -

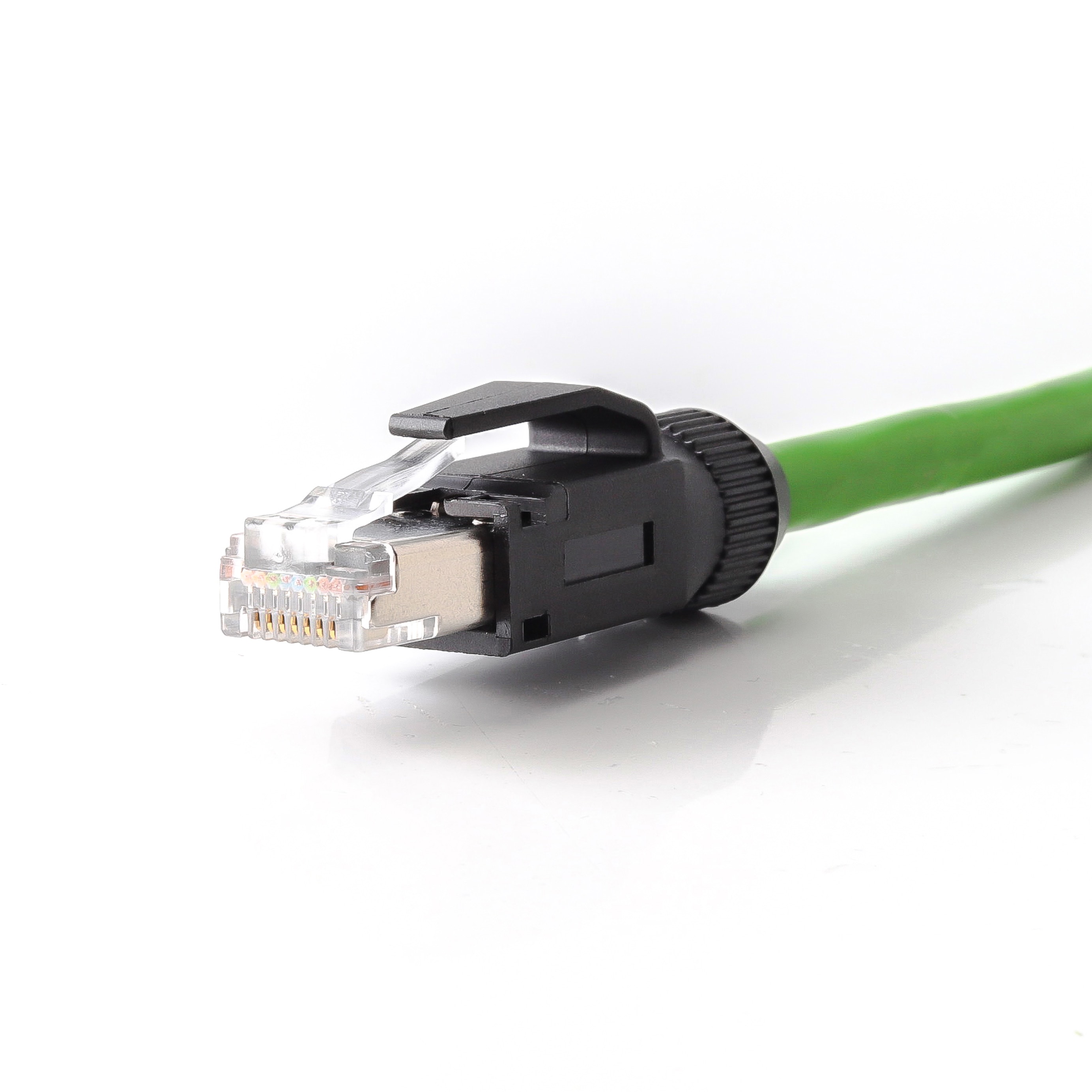

P/N: EhterNet Cable

EhterNet Cable CAT5/CAT6/CAT7 PROFIBUS Industrial Network cableView All -

P/N: AM12M0814X221-010

M12 X Code Male ProfiNET/EtherNET Cable M12 Connector X CodedView All

-

P/N: AM12F0411D241-010

M12 4P D Code Pre-molded Cable Connector Female Straight IP67View All -

P/N: AM78M0411A272-050

DeviceNET 7/8View All -

P/N: AM12F0411BXX1-XXX

M12 pre-molded cable connector, female, contacts:4, solder connection, B code, straight, IP67View All -

P/N: AM12F0511A241-010

M12 FieldBUS Cable Industrial Automation DeviceNet CanOpen CableView All -

P/N: AM78M0511A172-030

MINI-Change 7/8View All

-

P/N: AM12M0411D241-010

M12 pre-molded cable connector male solder connection D code straight IP67View All -

P/N: AM12F0812X003

M12 Device Connector X Code Female EMC Shielded Panel Rear Mount ReceptacleView All -

P/N: AM12M0811X231-030

M12 Pre-molded Cable Connector 8Pole Male X Code Cable StraightView All -

P/N: EhterNet Cable

EhterNet Cable CAT5/CAT6/CAT7 PROFIBUS Industrial Network cableView All -

P/N: AM12M0811YXX1-XXX

M12 Hybrid Connector,Male,M12 Y-Coded Power Signal Ethernet CableView All -

P/N: AM12F0811YXX1-XXX

M12 Hybrid Connector,Female,Power Signal,M12 Y-Coded CablesView All -

P/N: AM12F0812Y003

M12 Hybrid Connector,Female,Panel Mount Shielded,M12 Y-CodedView All

-

P/N: AM78H0511A433-XXX

Electrical Automation Power Supply Connector Cable 7/8-16UNF Pre-molded H-SplitterView All -

P/N: AM12H0811AXX1-XXX

M12 A Code 8P/4P Connector Y-Splitter Industrial Automation Sensor CableView All -

P/N: AM08Y0411A001-000

M8 Y-Splitter Electrical Automation Sensor Connector AdapterView All

Underwater Connectors and Cables

-

P/N: RMK5F

RMK5F 2, 3, 4, 5, 6 And 8 Contacts Deepsea Watertight ConnectorsView All -

P/N: MCDLS-F

MCDLS-F 2, 3, 4, 5, 6 and 8 contacts Deepsea Watertight ConnectorsView All -

P/N: MCBH5MTI

MCBH5MTI 2, 3, 4, 5, 6 And 8 Contacts Deepsea Watertight ConnectorsView All -

P/N: HPBH9M

HPBH9M 9 Contacts Deepsea Watertight ConnectorsView All -

P/N: HF75 50CXBH6F

HF75 50CXBH6F 6 Contacts Deepsea Watertight ConnectorsView All -

P/N: DMCIL13F M

DMCIL13F M 13 contacts Underwater cable connectorView All -

P/N: AWQ7-42

AWQ7-42 24, 28, 32, 36, 42 contacts Underwater cable connectorView All -

P/N: 1L25F M

1L25F M Circular 12, 16, 25 Contacts Underwater ConnectorView All

company

News

-

Amissiontech to Showcase Smart Interconnection Solutions at SPS 2025 in NurembergView All

Amissiontech to Showcase Smart Interconnection Solutions at SPS 2025 in NurembergView All -

2025 Tokyo International Manufacturing Expo: A Perfect ConclusionView All

2025 Tokyo International Manufacturing Expo: A Perfect ConclusionView All -

Amissiontech to Showcase Advanced Industrial Connectors and I/O Solutions at Manufacturing World Japan 2025View All

Amissiontech to Showcase Advanced Industrial Connectors and I/O Solutions at Manufacturing World Japan 2025View All -

Amissiontech Reflects on a Successful Participation at ProPak China 2025View All

Amissiontech Reflects on a Successful Participation at ProPak China 2025View All -

Amissiontech Team-Building Activity at Hailing IslandView All

Amissiontech Team-Building Activity at Hailing IslandView All -

Dragon Boat Festival Greetings: Celebrating Tradition with AmissiontechView All

Dragon Boat Festival Greetings: Celebrating Tradition with AmissiontechView All -

Celebrating Women at Amissiontech on International Women’s DayView All

Celebrating Women at Amissiontech on International Women’s DayView All -

Amissiontech Invites You to HANNOVER MESSE 2025View All

Amissiontech Invites You to HANNOVER MESSE 2025View All

-

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All -

What is an M12 A coded connector?View All

What is an M12 A coded connector?View All -

What Do You Know M12 B Coded?View All

What Do You Know M12 B Coded?View All -

Revolutionizing Field I/O Signal Transmission with Amissiontech's IO-Link HUBView All

Revolutionizing Field I/O Signal Transmission with Amissiontech's IO-Link HUBView All -

Exploring the Technology Behind Underwater Connectors and CablesView All

Exploring the Technology Behind Underwater Connectors and CablesView All -

Amissiontech's IO-LINK Modules Shine at HANNOVER MESSE 2024View All

Amissiontech's IO-LINK Modules Shine at HANNOVER MESSE 2024View All -

Circular ConnectorView All

Circular ConnectorView All -

IO-Link Module - Connects Future Digital CommunicationsView All

IO-Link Module - Connects Future Digital CommunicationsView All

-

Understanding Ethernet MHz Speed and Its Impact on Network PerformanceView All

Understanding Ethernet MHz Speed and Its Impact on Network PerformanceView All -

Top 10 Cable Types and Their UsesView All

Top 10 Cable Types and Their UsesView All -

HDMI vs VGA: Understanding the Key Differences for Industrial & Custom Cable ApplicationsView All

HDMI vs VGA: Understanding the Key Differences for Industrial & Custom Cable ApplicationsView All -

Complete Guide to Ethernet Cable CategoriesView All

Complete Guide to Ethernet Cable CategoriesView All -

Wire Harness Production ExplainedView All

Wire Harness Production ExplainedView All -

Industrial HDMI Shielded Cable Technology InterpretationView All

Industrial HDMI Shielded Cable Technology InterpretationView All -

Revolutionize Automation with DeviceNet-Compatible ToolsView All

Revolutionize Automation with DeviceNet-Compatible ToolsView All -

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All

Amissiontech IO-Link Modules: Versatility in Connection MethodsView All

Industries and Solutions

Solutions

Industries

News And Events

How to Diagnose and Repair M12 Code Connector Cable Issues

M12 connections are circular connectors with a 12-mm locking thread that are commonly used in factory automation applications for sensors, actuators, Fieldbus, and industrial Ethernet.

They are often rated IP65, IP68, or IP69K, making them appropriate for washdown and corrosive situations.

M12 code connectors are a critical component of any electrical system. If they don't function properly, the rest of the network will as well.

The performance of a defective connector would be slowed by any type of disruption.

Contacting a good manufacturer of the product is advisable whenever you are in need to for M12 code connectors to transmit power or data in your organization.

Here, we'll look at some of the symptoms that suggest whether or not your code connector is working up to par.

· Your connection is always sluggish.

There's a good probability you have a damaged connector if your connection continues dropping or running slowly.

A tear in your cable can also compromise the internal wire connection, resulting in a short circuit.

Try straightening a bent cable with your hands if you discover one. You'll have to replace it if it's too worn out.

· With A Wiggle, The Connection Was Restored

A failed connection can be re-established by wriggling the connector.

If you do this too frequently, you'll have a broken connector on your hands.

A plastic lever integrated into M12 code connector locks the cable in place within the adapter port. The connection will fall if this lever breaks.

· Frequently loses contact.

If the light does not turn on when you insert the cable into the adapter, it could be an issue with the cable or the connector.

If you observe display warnings like 'network connection lost' or 'no connection,' something is amiss with the M12 cable connector on the system.

In such circumstances, double-check that the cable is correctly connected. A defective cable, even if correctly connected, will not work otherwise.

· Do You Continually Replace Them?

This is the clearest indication that your network ecology requires attention. If replacing the M12 code connector solves the problem, then everything is fine.

However, if the problem persists with the new connector, the issue is network related. It's possible that anything is wrong.

· Continuity Issues Must Be Tested

Continuity issues might develop if there are any broken connectors or bends in a cable.

A cut or sliced cable, any type of penetration by things such as a nail, staple, screw, or other object, or electromagnetic interference can all cause them.

Check for any of these causes if you can visually inspect the code connector. If not, use a continuity tester to check it.

This is accomplished by the use of an electrical gadget. Such a device can help detect problems caused by EMI, or radio frequency interference.

· Troubleshooting Connectivity Problems

The most common source of these problems is a defective cable. Consider running a brief test to see if the connection is working.

To test, connect the suspected connector to another computer's network device or network connector.

The jack into which you plug the connector is usually part of a network adaptor.

It serves as a connection point between a computer or network device and a network cable.

Contact us for premium M12 code connectors

If you are looking to buy new M12 code connector for transmission of data and electric signals, you can navigate to our page from here. We have all the code connector to fulfill your requirements.

Do contact us for a durable and highly-efficient code connector.