1. Introduction

Cables play a critical role in modern electrical and communication systems, serving as the backbone for power transmission and data connectivity. Whether in industrial plants, commercial buildings, transportation systems, or data centers, cables ensure that energy and signals flow reliably from one point to another.

However, due to environmental stress, mechanical damage, aging, or improper installation, cable faults are common occurrences. These faults can lead to system downtime, equipment failure, and even safety hazards. Understanding the types of cable faults, their causes, and effective detection and repair methods is essential for maintaining system integrity and operational efficiency.

This article provides a comprehensive overview of common cable faults, including their identification, analysis, troubleshooting techniques, and preventive strategies. It aims to serve as a practical reference for engineers, technicians, and maintenance personnel involved in electrical and communication infrastructure.

2. Types of Cables and Applications

Classification by Application

Power Cables

Designed to transmit electrical energy, power cables are widely used in power distribution systems, including substations, industrial facilities, and residential buildings. They vary by voltage level — low voltage (LV), medium voltage (MV), and high voltage (HV) — and may include features such as fire resistance or flame retardancy for enhanced safety.

Control Cables

Used for transmitting control signals in automation systems, control cables are essential in manufacturing lines, machinery control panels, and building management systems. These cables often include shielding to protect against electromagnetic interference (EMI) and ensure signal accuracy.

Communication Cables

These cables support data and signal transmission in telecommunications and networking applications. Common types include twisted pair cables, coaxial cables, and fiber optic cables. Fiber optics, known for their high bandwidth and low signal loss, are increasingly used in high-speed internet, cloud computing, and long-distance communication networks.

Classification by Construction

Single-core vs. Multi-core Cables

A single-core cable contains one conductor and is typically used in high-voltage applications where flexibility is less critical. Multi-core cables contain multiple conductors within a single sheath, making them ideal for complex wiring systems in buildings and control circuits.

Shielded vs. Unshielded Cables

Shielded cables feature a metallic layer to reduce electromagnetic interference and are commonly used in sensitive electronic environments. Unshielded cables are more cost-effective but are best suited for areas with minimal EMI exposure.

Armored vs. Unarmored Cables

Armored cables have an additional protective layer, usually made of steel or aluminum, to enhance mechanical strength and resist physical damage. These are often used in underground installations or harsh industrial environments. Unarmored cables lack this protection and are suitable for indoor or light-duty applications.

Typical Application Scenarios

Industrial Automation: Control and signal cables connect PLCs, sensors, and actuators on production lines.

Building Electrical Systems: Power cables supply electricity to lighting, HVAC, and appliances, while communication cables support security and smart building systems.

Transportation Infrastructure: Railways and subways use specialized cables for traction power, signaling, and onboard systems.

Data Centers: High-performance communication cables ensure fast and stable network connections between servers and storage devices.

Renewable Energy Systems: In wind farms and solar power plants, power cables transport generated electricity to the grid, requiring durability under extreme conditions.

3. Main Causes of Cable Failures

Cable failures can occur due to a variety of internal and external factors. Identifying the root causes is essential for effective troubleshooting, repair, and prevention. The most common causes include:

Environmental Factors

Environmental conditions play a significant role in cable degradation. Exposure to extreme temperatures, moisture, UV radiation, and chemical substances can accelerate insulation aging and lead to faults. For example, water ingress can cause insulation breakdown, while prolonged exposure to sunlight may degrade the outer sheath.

Mechanical Damage

Physical damage during installation, operation, or maintenance is a major cause of cable failure. This includes:

Excessive bending beyond the minimum bend radius

Crushed or cut cables during excavation or construction

Improper handling leading to conductor breakage or insulation cracks

Such mechanical stress can compromise both the structural integrity and electrical performance of the cable.

Manufacturing Defects

Poor quality materials or substandard manufacturing processes may result in weak spots within the cable. These defects may not be immediately apparent but can lead to premature failure under normal operating conditions. Common issues include uneven insulation thickness, impurities in conductor material, and improper shielding.

Aging and Electrical Stress

Over time, cables naturally degrade due to thermal cycling, oxidation, and long-term exposure to voltage stress. Repeated overloading or voltage surges — such as those caused by lightning strikes or switching operations — can further accelerate this process. Insulation becomes brittle and less effective, increasing the risk of short circuits and ground faults.

Understanding these main causes helps engineers and technicians implement better design, installation, and maintenance practices to minimize cable failures and extend system life.

4. Common Types of Cable Faults

Cable faults can manifest in various forms, each with distinct characteristics and implications. Recognizing the type of fault is crucial for accurate diagnosis and appropriate corrective action.

Open Circuit Fault

An open circuit fault occurs when the continuity of the conductor is interrupted, preventing current flow. This is often caused by broken conductors, loose connections, or failed terminations. Symptoms include complete loss of power or signal transmission in the affected line.

Short Circuit Fault

A short circuit happens when two or more conductors come into unintended contact, allowing current to bypass the intended load. This results in excessive current flow that can trigger protective devices (e.g., circuit breakers) and potentially damage equipment. Common causes include insulation breakdown and physical damage.

Ground Fault

A ground fault occurs when current unintentionally flows from a live conductor to the ground or grounded surface. This is typically due to damaged insulation or moisture ingress. Ground faults pose serious safety risks and may cause electric shocks or fire hazards.

Insulation Failure

Insulation failure refers to the deterioration or breakdown of the insulating material surrounding the conductor. It can lead to leakage currents, partial discharges, or full insulation collapse. Aging, overheating, and environmental exposure are the primary contributors to this type of fault.

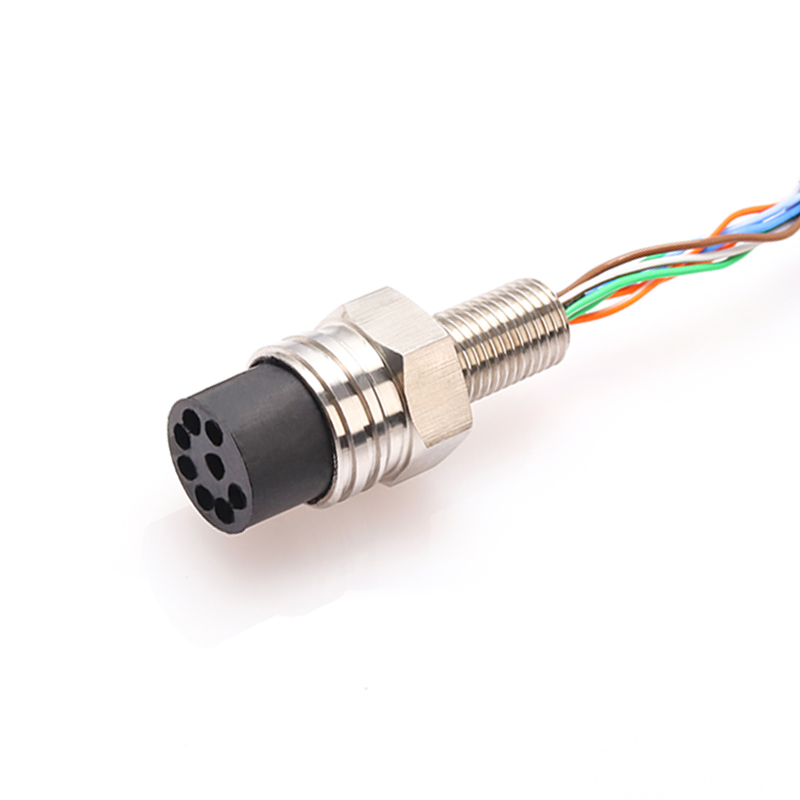

Termination and Connector Faults

Faults at cable terminations or connectors are common in both power and data cables. Poor crimping, corrosion, or misalignment can increase contact resistance, causing overheating and intermittent connectivity. These faults are particularly prevalent in frequently plugged/unplugged systems.

Electromagnetic Interference (EMI)

Although not a direct physical fault, EMI can disrupt signal integrity in communication and control cables. It is usually caused by inadequate shielding, poor cable routing near high-voltage lines, or ungrounded metal components. Symptoms include data corruption, signal distortion, and communication errors.

By understanding these common types of cable faults and their underlying causes, maintenance personnel can better diagnose problems and apply targeted solutions to restore system performance.

5. Cable Fault Detection Methods

Detecting cable faults accurately and efficiently is crucial for minimizing system downtime and ensuring safe operation. Various testing and diagnostic techniques are used depending on the type and location of the fault.

Visual Inspection

A basic but essential step in fault detection, visual inspection involves examining the cable’s outer sheath and termination points for signs of physical damage, wear, or corrosion. Although it cannot identify internal issues, it helps detect obvious causes such as cuts or abrasions.

Continuity and Resistance Testing

Using a multimeter or ohmmeter, continuity testing checks whether the conductor remains intact between two points. High resistance readings may indicate partial breaks or poor connections.

Insulation Resistance Testing (Megger Test)

This test measures the resistance between conductors and ground or between conductors to assess insulation condition. A significant drop in resistance indicates potential insulation breakdown or moisture ingress.

Time Domain Reflectometry (TDR)

TDR sends a low-voltage pulse along the cable and analyzes the reflected signal. By measuring the time delay and magnitude of the reflection, TDR can locate open circuits, short circuits, and impedance mismatches with high accuracy.

High Voltage Withstand Testing

Also known as a dielectric strength test, this method applies a high voltage across the cable insulation to check its ability to withstand electrical stress without breakdown. It helps identify weak spots that may lead to future failures.

Partial Discharge Testing

Used primarily for medium- and high-voltage cables, partial discharge (PD) testing detects small electrical discharges within the insulation. These discharges often precede full insulation failure, making PD testing a valuable predictive maintenance tool.

Infrared Thermography

Thermal imaging cameras detect abnormal temperature patterns in cables and connectors. Overheating due to high resistance or overloading can be identified early using this non-contact technique.

These methods, when used individually or in combination, provide a comprehensive approach to identifying and locating cable faults effectively.

6. Solutions for Common Cable Faults

Once a cable fault has been detected and analyzed, appropriate corrective actions must be taken to restore system functionality and prevent recurrence.

Open Circuit Faults: Replace the damaged section of the cable or re-terminate the affected end. If caused by mechanical stress, ensure proper routing and support during reinstallation.

Short Circuit Faults:Cut out the damaged portion and install a new splice or joint. If insulation failure is widespread, consider replacing the entire cable segment. Use higher-grade insulation materials if environmental factors contributed to the fault.

Ground Faults: Locate and repair any insulation breaches or moisture entry points. Apply waterproof tape or heat-shrink tubing to seal the damaged area. In severe cases, replace the affected section with a more durable cable.

Insulation Failure: Depending on the severity, either repair the damaged insulation or replace the entire cable. Improve protection against environmental stress by installing protective conduits or using cables with better thermal and chemical resistance.

Termination and Connector Faults: Re-crimp or resolder faulty connections. Replace corroded or worn-out connectors. Apply anti-oxidation paste to improve conductivity and prevent future degradation.

Electromagnetic Interference (EMI): Upgrade to shielded cables where interference is an issue. Rearrange cable routing to avoid proximity to high-current lines. Ensure all shielding layers are properly grounded.

By applying these targeted solutions, technicians can restore cable performance and extend service life while addressing the root cause of each specific fault.

7. Prevention Strategies

Preventing cable faults requires a proactive approach that includes proper design, installation, maintenance, and monitoring practices.

Proper Cable Selection and Installation

Choosing the right cable for the application is critical. Consider factors such as voltage rating, current capacity, environmental conditions, and mechanical protection. During installation:

Avoid sharp bends and excessive tension

Follow minimum bend radius guidelines

Secure cables with appropriate clamps and supports

Regular Maintenance and Testing

Implement a scheduled maintenance plan that includes:

Regular testing helps identify early signs of degradation before they develop into serious faults.

Environmental Protection

Protect cables from harsh environmental conditions by:

Using UV-resistant and flame-retardant jackets

Installing cables in conduits or cable trays

Sealing outdoor terminations against moisture

Personnel Training

Ensure that installation and maintenance personnel receive proper training on:

Well-trained staff significantly reduce the risk of human error-related faults.

Use of Monitoring Systems

Modern cable monitoring systems provide real-time data on:

Temperature

Load current

Insulation condition

These systems enable predictive maintenance and help prevent unexpected failures.

Adopting a comprehensive prevention strategy not only reduces downtime but also improves overall system reliability and cost efficiency.

Conclusion

Cables are essential components in electrical and communication systems, and their reliability directly affects the performance and safety of the entire infrastructure. Understanding the common types of cable faults — including open circuits, short circuits, ground faults, and insulation failures — is key to effective troubleshooting and repair.

Faults can arise from various causes such as environmental exposure, mechanical damage, manufacturing defects, and long-term aging. Identifying these causes allows for more accurate diagnosis and targeted corrective action.

Several detection methods, including visual inspection, insulation resistance testing, TDR, and infrared thermography, provide reliable tools for locating and diagnosing faults. Once identified, appropriate solutions such as cable replacement, splicing, connector repair, or EMI mitigation can be applied to restore system integrity.

Preventive measures — from proper selection and installation to regular maintenance, environmental protection, and personnel training — play a vital role in minimizing the occurrence of cable faults. Implementing intelligent monitoring systems further enhances fault prediction and response capabilities.

By combining technical knowledge with best practices in design, installation, and maintenance, engineers and technicians can ensure the long-term reliability and safety of cable-based systems across various industries.

Choose Amissiontech for Custom High-Performance Cable Solutions

At Amissiontech, we specialize in designing and manufacturing custom cable harnesses and industrial interconnect solutions tailored to your unique requirements. Our 2000m² R&D center and rigorous testing processes ensure that every cable performs reliably under real-world conditions. Whether for industrial control, automation, transportation, or energy systems — trust Amissiontech to deliver cables that go the distance.

EN

EN DE

DE JP

JP ES

ES SE

SE FR

FR IT

IT CN

CN 한국어

한국어 ภาษาไทย

ภาษาไทย بالعربية

بالعربية Nederlands

Nederlands Türkçe

Türkçe Język polski

Język polski Tiếng Việt

Tiếng Việt Zulu

Zulu Bahasa Malay

Bahasa Malay